Technical specification

bg

Model

JZM120

Production capacity

100-150kg/h

Diameter of the product

20-50mm

steam consumption

250kg/h

steam pressure

02.-06mpa

Room temperature

20-25

grocess weight

8000kgs

The length of the line

approx 35m

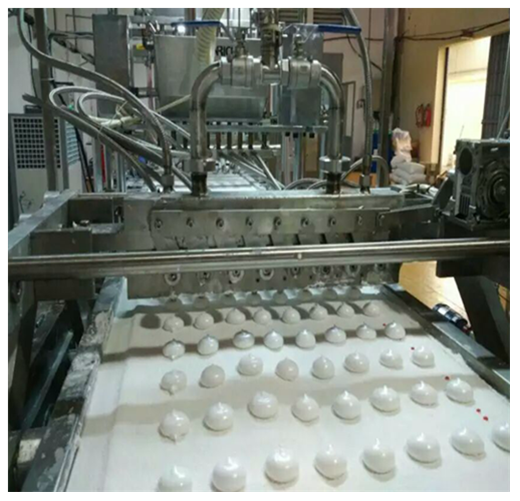

An automatic cotton candy production line is a piece of cotton candy production equipment. This extruded cotton candy line consists of a depositing machine and an extruder, capable of producing filled cotton candy or twisted, multi-colored cotton candy. This machine allows you to quickly and conveniently create a variety of cotton candy types, sizes, and colors. If you're considering purchasing a filled cotton candy production line from China, we're your top choice.

++

Our state-of-the-art marshmallow and marshmallow cooking system is crucial to producing high-quality marshmallow confectionery—each one must be soft and tender.

Our brewing system is designed to create the perfect syrup. It combines the latest technology, a step-by-step process, precise temperature settings, and meticulous stirring techniques to ensure the desired consistency is consistently achieved throughout the brewing process.

++

We have a complete, fully automated continuous production line that can produce high-quality marshmallows in a variety of colors, shapes, and fillings. The line has flexible extrusion capabilities and can produce a variety of special shapes and forms of marshmallows to meet various product needs, including cartoon shapes, twisted rope shapes, and fruit fillings.

++

Final Product

Fully automatic marshmallow production line – Prefect for various shapes and fillings

Premium Texture: Our creation machines produce highly aerated marshmallows with a smooth, fluffy, and soft texture. This equipment ensures a consistently fluffy texture and light quality, delivering the desired texture through precise control and advanced technology.

Multiple Shapes and Colors: The extruder's single nozzle can produce up to four colors simultaneously, enabling a variety of shapes and twists of marshmallow ropes. It supports the production of different colors and specific shapes, and allows for the combination of flavors and fillings for maximum customization.

Innovative Fillings and Combinations: The depositing machine can create filled marshmallows (such as jam or chocolate) as well as two-toned marshmallows with fillings similar to ice cream. The system can produce a wide range of marshmallow flavors and flavor combinations, including two-toned and filled varieties.

Seamless Automation: The integrated automatic drying system eliminates the need for human intervention until packaging is complete, streamlining the production process. This technology and system are designed to streamline operations, reduce labor costs, and achieve high production efficiency by minimizing human intervention and labor costs.

End-to-End Solution: This continuous aeration line is a complete system that handles all steps from raw material boiling to drying and packaging. The cotton candy machine and its components are constructed of stainless steel, ensuring food safety and hygiene. The production process is well-designed, cost-effective, and minimizes waste.

Maximum Customization: Single-color and multi-color cotton candy can be produced, along with twisted and cartoon shapes, ice cream designs, and fruit fillings. This system meets the market needs and product requirements of the confectionery industry and businesses, including the ability to produce a wide range of confectionery products in a factory setting.

1 year wearing spares supply

Economical and high efficiency of the whole solution supply

Supply turn-turkey line from A-Z

High quality confectionery and chocolate processing machinery

Professional machinery designer and manufacturer

Some of Customer list brand

bg

![Sandwich Cotton Candy Production Line Marshmallow Extruding Machine JZM120 12]()

b

Fully Automated Marshmallow Production Line – Operator Checklist

────────────────────────────

Pre-Mixer

• Prepares the mixture by adding water, sugar, glucose syrup, gelatin solution (or other hydrocolloids), heat-resistant color/flavoring, and corn syrup as the main ingredients.

• Setup: Dissolve at 75–80°C, 60–90 rpm, until a Brix of 78–80°C is reached.

• Ensures consistency of the mixture for a highly aerated candy product.

• CIP rinse sequence at the end of the batch.

Cooker (flash or tube)

• Continuous feed from pre-mixer.

• Target: 105–110°C, final moisture 18–22%.

• Online refractometer alarm if Brix < 76°C.

Slurry Cooler

• Plate heat exchanger temperature to 65–70°C.

• Critical: Avoid temperatures below 60°C (to prevent gelatin pre-coagulation).

Continuous Aerator

• Set to 250–300% overrun.

• Air flow meter: 3–6 bar, sterile filtered.

• Check torque curve—peaks indicate clogged screen.

Deposition Function Center Fill for 3D Shapes

• Manifold separates the base into 2–3 colors, creating a marshmallow.

• Peristaltic pump allows for metered addition of heat-sensitive flavors (< 45°C) and coloring.

• Verify flow rate ratios match the recipe sheet.

Four colors are extruded into a single marshmallow roll

• Mold temperature 45–48°C (to prevent tearing).

• Cooling tunnel: 15–18°C, dwell time 4–6 minutes, RH < 55%.

• Belt speed synchronized with downstream cutter.

Dust removal chamber (starch/icing)

• Top and bottom dust collectors set to 1.5–2 grams per 100 grams of product.

• Rotary blades cut to ±1 mm length.

• Chamber pressure -25 Pa; HEPA exhaust.

• Use of powder helps prevent sticking and maintain product quality.

Dust removal/excess dust removal

• Vibrator + reverse air knife removes excess starch.

• Inline metal detector after vibrator.

• Additional dust removal helps prevent sticking and ensure product integrity.

Automatic drying belt and system

• 25-35°C, humidity <55%

• Cooling tunnel 12–15°C, 6–8 minutes.

Packaging

• Transfer to the flow wrapper via a distribution belt.

• MAP option: N₂ flushing, O₂ <1%.

• Seal integrity checked (vacuum decay test every 30 minutes).

• The packaging stage is the final step in the production process, extending shelf life and ensuring food safety.

Safety/Quality Information

• All stainless steel contact parts are 304 or 316; complete CIP/SIP cycles.

• Critical Control Points (CCP): Cooking temperature, metal detection, package sealing.

• Typical output: 1.2 m extrusion line, 300–500 kg/h.