Manyan masu samar da kayan ƙanshi na sukari masu tauri. WhatsApp|Wechat: +8613801127507, +8613955966088

Jagorar Ƙarshen Layin Samar da Gummy Candy: Gano Yadda Ake Yin Gummy Bears

An daɗe ana amfani da alewar Gummy a tsakanin masoyan alewa saboda laushin laushinsu da launuka masu haske. Wannan labarin zai yi bayani game da takamaiman injuna da layukan samarwa da ake amfani da su wajen samar da alewar gummy, da kuma nau'ikan layukan samar da alewar gummy da ake buƙata don nau'ikan alewar gummy daban-daban. Zai gano sirrin kera alewar gummy da kuma yadda layukan samar da alewar gummy ke aiki. Injinan samar da alewar gummy masu ƙirƙira na iya samar da siffofi da dandano na alewar gummy masu ƙirƙira, wanda hakan zai fara kasuwancin alewar gummy ɗinku!

Shahararriyar Candy a Kasuwa

Ana ɗaukar alewar Gummy a matsayin abin ciye-ciye mai daɗi da daɗi wanda ba wai kawai yana gamsar da sha'awa mai daɗi ba, har ma yana ba da kuzari da ɗanɗano mai daɗi. Lewar Gummy wani yanayi ne da ya shahara, musamman a tsakanin matasa.

A kasuwa, kamfanoni da masana'antun daban-daban suna bayar da nau'ikan alewa iri-iri na gummy a cikin dandano, siffofi, da tsari daban-daban don biyan buƙatun masu amfani daban-daban. Wasu kamfanoni sun kuma gabatar da alewa masu amfani da gummy, kamar waɗanda ke da ƙarin bitamin, zare, da sauran sinadarai masu lafiya, da kuma alewa na gummy na musamman.

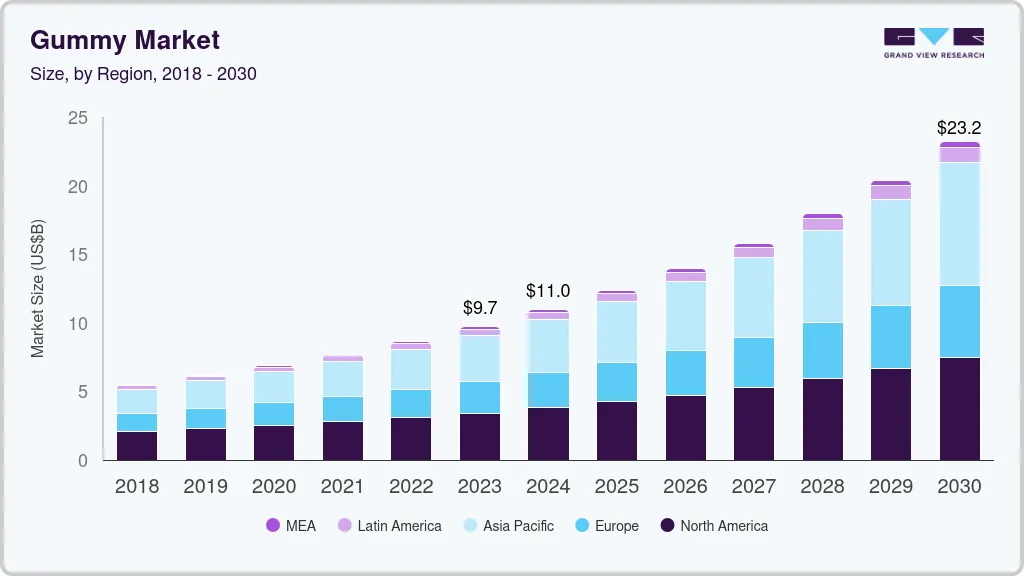

A matsayin ƙaramin abun ciye-ciye, alewar gummy ba wai kawai ta shahara a tsakanin yara ba, har ma matasa da manya suna jin daɗinta. alewar gummy tana zuwa da dandano da siffofi iri-iri, tare da ƙirar marufi mai kyau, wanda ke jan hankalin masu amfani na kowane zamani. Bugu da ƙari, tare da ƙara wayar da kan jama'a game da lafiya da abinci mai gina jiki, samfuran alewar gummy marasa sukari da sukari suna samun karbuwa, suna ƙara faɗaɗa kasuwa. An kiyasta kasuwar alewar gummy ta duniya a kan dala biliyan 23 a shekarar 2024 kuma ana hasashen za ta girma a cikin adadin ci gaban shekara-shekara sama da kashi 10.4% daga 2025 zuwa 2034. Kasuwar alewar gummy ta duniya tana fuskantar ƙaruwar alewar gummy masu aiki, suna ba da fa'idodi ga lafiya fiye da na alewar gargajiya.

Bears Gummy Mafi Sayarwa

Beyar Gummy sun samar da wani muhimmin wuri a cikin al'umma tare da ɗanɗano mai ban sha'awa, laushi, da kuma sha'awar tunawa. Beyar Gummy ta fara bayyana a Jamus a shekarun 1980, kuma cikin ƙarni guda, sun sami karbuwa da karɓuwa sosai a duk duniya. Tsarin taunawarsu yana ba da kyakkyawar gogewa ta ji, yayin da ɗanɗanon 'ya'yan itacensu yana sa su zama abin sha'awa ga yara da manya. Shahararrun samfuran kamar Haribo sun taimaka wajen ɗaga beyar gummy zuwa shahararru. Sakamakon haka, suna iya samar da ɗanɗano da jin daɗi daidai, wanda hakan ya sa beyar gummy ta zama cikakkiyar alewar 'ya'yan itace mai daɗi.

Yaya tsarin samar da alewar jelly yake?

Injinan da ake amfani da su wajen samar da alewar gummi yawanci suna bin tsari makamancin haka:

Shiri: Ana shirya sinadaran, kamar pectin ko gelatin, ruwa, sukari, dandano, da launuka, kuma ana auna su bisa ga girke-girken da ake so.

Haɗawa: Ana haɗa sinadaran a cikin babban tukunya ko tanki. Ana dumama cakuda kuma ana juyawa don narke sukari da kunna sinadarin gelling (pectin ko gelatin). Ana ƙara ɗanɗano da launuka a wannan matakin.

Dafawa : Ana dumama hadin zuwa wani zafin jiki na musamman domin tabbatar da cewa sinadarin gelling ya yi daidai. Wannan matakin yana haifar da samuwar tsari mai kama da gel a cikin alewar gummy.

Sanyaya da Sanyaya: Bayan dafawa, ana barin hadin ya huce zuwa yanayin zafi da ya dace. A wannan matakin, ana sanyaya hadin alewar gumi, wanda ke taimakawa wajen cimma yanayin da ake so da kuma daidaiton da ake so.

Samarwa: Daga nan sai a zuba hadin alewar gummy a cikin wata na'ura da ake kira depositor. Mai ajiya yawanci yana kunshe da jerin bututu ko molds da ake amfani da su wajen rarraba hadin alewar gummy zuwa wasu siffofi, kamar beyar, tsutsotsi, ko 'ya'yan itace. Wannan na'urar tana tabbatar da cewa an rarraba hadin alewar gummy daidai a cikin molds.

Sanyaya da Saiti: Da zarar an saka hadin alewar gummy a cikin molds, ana mayar da shi zuwa ramin sanyaya ko bel ɗin jigilar kaya. Wannan yana bawa alewar damar sanyaya da tauri, wanda hakan ke ba su damar riƙe siffarsu.

Rufewa da Dubawa: Bayan alewar ta yi ƙarfi gaba ɗaya ta kuma sanyaya, ana cire ta daga mold ɗin. Ana iya yin hakan da hannu ko kuma da taimakon injin rushewa ta atomatik. Sannan ana duba alewar don tabbatar da inganci, ana duba duk wani lahani ko lahani.

Waɗannan matakai na iya bambanta dangane da takamaiman kayan aiki da hanyoyin da masana'antun daban-daban ke amfani da su. Duk da haka, babban burin shine a samar da adadi mai yawa na alewa cikin inganci tare da kiyaye inganci da siffa mai daidaito.

Ta yaya Jelly Candy Production Line ke aiki?

Babban aikin layin samar da alewa shine canza kayan da aka yi amfani da su kamar sukari, manne, ruwa, da dandano/kala zuwa alewa ta atomatik tare da siffa iri ɗaya, laushi mai laushi, da kuma tsawon lokacin shiryawa. Ana iya ɗaukar dukkan tsarin a matsayin manyan matakai shida: sinadaran → tafasa → dandano da launi → zuba → sanyaya da siffa → rushewa → busarwa. Waɗannan matakan ana sarrafa su ta tsakiya ta hanyar PLC kuma suna gudana akai-akai ko kuma lokaci-lokaci.

Sinadaran da Kafin a Yi Magani

Ana ciyar da daskararru (kamar sukari, syrup, gelatin/pectin/carrageenan, da sitaci) a cikin abin auna nauyi ta hanyar tsotsar injin ko kuma lif. Ana aika dabarar daga MES zuwa PLC, tare da kuskuren ≤±0.5%.

Dole ne a jiƙa Colloids kafin a fara zubawa: dole ne su kumbura a cikin ruwa mai tsarki a zafin 60-70°C na minti 20-30, sannan a ɗauki matakin "magani" a zafin 85-90°C na minti 20 don buɗe colloids gaba ɗaya da kuma rage kololuwar ɗanko a ƙarshen baya. In ba haka ba, "wutsiya" ko "ƙarfin gwiwa" zai bayyana yayin zubawa.

Tafasar sukari

Da farko ana dumama sukari da ruwa a cikin tukunya mai narkewar sukari zuwa 106–108°C, wanda ke kaiwa ga narkewar kusan 75%. Sannan ana tura sukarin zuwa injin tafasa sukari mai sirara (ko tankin girki na injin) don ƙafewa a 105–115°C a ƙarƙashin injin 0.6–0.8. Wannan tsari yana rage yawan danshi zuwa 12%–14% a cikin mintuna 3-5, yana hana launin ruwan kasa a yanayin zafi mai yawa yayin da yake kiyaye ɗanko na 1200–1800 mPa·s don zubarwa daga baya.

Tsarin injin tsabtace iska yana kuma cire ƙananan kumfa, yana ƙara haske ga alewar mai laushi. Tsarin dawo da tururi yana canza tururin na biyu zuwa ruwan zafi mai zafi na 80°C wanda aka mayar da shi cikin tukunyar, wanda ke adana kusan kashi 30% na kuzari.

Ɗanɗanon Kan layi, Launi, da Tsaftace Acid

Maganin gelatin na sukari da aka dafa yana shiga cikin tsarin "mai haɗa sinadarai masu tsauri + dandano/ƙarfafawa ta yanar gizo". Ana allurar daɗaɗɗen dandano, launi, citric acid/malic acid, da sinadaran aiki (bitamin, probiotics, da sauransu) ta hanyar famfunan auna servo a rabo na 0.1%–1%. Lokacin haɗawa shine ƙasa da daƙiƙa 10 don hana yawan acidity na gida daga haifar da coagulation na gelatin kafin ya yi aiki.

Zubawa da Gyara

Kan servo yana aiki a matsayin "metronome" ga dukkan layin samarwa. Yana amfani da famfon gear ko famfon plunger don allurar syrup na sukari mai zafi 85–90°C a cikin mold ɗin tare da daidaiton ±1%.

Sanyaya da Tsarin Farko

Modulation yana shiga ramin sanyaya a 10-15°C ta hanyar na'urar jigilar sarka. Matsin iska shine 0.8-1.2 kPa, yana sanyaya zafin sukari zuwa 25°C cikin mintuna 30. Hanyar sadarwar gelatin ta fara samar da kwarangwal mai laushi, kuma aikin ruwa (Aw) yana raguwa zuwa 0.65-0.70, wanda ke hana sukari mannewa a kan mold.

Rufewa da isar da kaya

Sitaci: A juya a girgiza 180°, a saka alewar mai laushi a cikin allon girgiza don raba sukari da foda; ana busar da sitaci a 60°C sannan a tace ta hanyar allo mai kauri 60 don sake amfani da shi, tare da asarar ƙasa da kashi 2%.

Nau'ikan Layin Samar da Candy na Gummy - Bayani

Layukan Ajiye Candy na Gummy

Layukan ajiya na alewa masu laushi suna aiki akai-akai a lokacin manyan ayyukan ƙera kayayyaki kuma saboda haka ana sarrafa su ta atomatik gaba ɗaya. Suna taimakawa wajen inganta inganci yayin da suke rage farashin aiki saboda ba sa buƙatar mai aiki ya kasance a kowane lokaci, ba kamar sauran nau'ikan da ke buƙatar dubawa akai-akai bayan wani lokaci ba.

● Ƙarfin Samarwa: 150–2000 kg/h

● Fa'idodi: Babban ƙimar fitarwa; inganci mai daidaito; ƙarancin buƙatun aiki

● Aikace-aikace: Samar da alewa mai laushi na gelatin/pectin, alewa mai laushi mai launuka biyu/cikakke, da alewa mai laushi mai aiki

Layukan Ciko na Candy Gummy

Cikakken layin cike alewa mai laushi ya ƙunshi tsarin girki na jelly, tsarin haɗa da haɗa FCA (ɗanɗano, launi, da acid), wurin adana alewa mai amfani da yawa, ramin sanyaya, da injin shafa sukari ko mai. ● Ƙarfin Samarwa: 200–800 kg/h

● Fa'idodi: Babban daidaito; sauƙin daidaitawa; ƙarancin ɓatar da kayan aiki yayin samarwa

● Aikace-aikace: Samar da alewa mai cike da gummy, alewa mai cike da bitamin gummy, alewa mai jelly gummy, da alewa mai siffar ƙwallo

Jelly Candy Sitaci Molding Line

Ana amfani da injin ajiye sitaci musamman don samar da alewar sitaci mai kama da sitaci. Duk layin ya haɗa da tafasa, gyaran fuska, shafa foda ta atomatik, jika (wanda zai iya cikawa, jika launuka biyu na hagu-dama, ko jika launuka biyu na sama-ƙasa bisa ga buƙatun abokin ciniki), raba sukari da foda, da tsarin dawo da foda.

● Ƙarfin Samarwa: 200–800 kg/h

● Fa'idodi: Babban daidaito; sauƙin daidaitawa; ƙarancin ɓatar da kayan aiki yayin samarwa

● Aikace-aikace: Samar da alewa mai tsami na gummy

Jelly Mogul Line

Layin Jelly Mogul wani layin samar da alewa ne mai inganci, mai sauƙin sarrafawa, aiki mai kyau, da kuma fitarwa mai yawa. Duk layin ya haɗa da tsarin girki, layin ƙira, tsarin sanyaya sitaci, tsarin tattara sitaci da dawo da sitaci, kammala kayan da aka gama, da tsarin tallafi.

● Ƙarfin Samarwa: 400–1500 kg/h

● Fa'idodi: Ana sarrafa yawan kwararar sirop daidai ta hanyar tsarin sarrafa mita mai canzawa, wanda ke tabbatar da kwanciyar hankali.

● Amfani: Ya dace da samar da alewa mai laushi da aka yi da sitaci, gelatin, carrageenan, gaurayen gumi, da sauran alewa masu laushi.

Layin Samar da Kayan Jelly na Mold 3D

Layin Ajiye Candy na Jelly Candy na 3D injin ajiye alewa ne mai laushi wanda ke amfani da molds masu ƙura. An tsara shi don samar da alewa masu laushi tare da siffofi da ƙira masu rikitarwa. Yana amfani da mold mai juyawa don cimma siffofi masu rikitarwa da rikitarwa.

● Ƙarfin Samarwa: 400–1500 kg/h

● Fa'idodi: Ana sarrafa yawan kwararar sirop daidai ta hanyar tsarin sarrafa mita mai canzawa, wanda ke tabbatar da kwanciyar hankali.

● Aikace-aikace: alewa mai laushi ta 3D kamar ƙwallon ido, beyar gummi, alewa ta 'ya'yan itace, da alewa mai siffar zane mai ban dariya.

Waɗanne irin alewa ne injin alewa na gummy zai iya yi?

Za ku iya amfani da layin samar da alewa na jelly don samar da alewa iri-iri: beyar gummi, alewa na jelly, alewa na pectin, wake na carrageenan, da sauransu:

● alewa mai siffar zuciya mai kama da na gumi

● alewa mai ɗanɗanon jelly ball

● alewa masu ɗanɗano a mashaya

● Beyar mai cin nama

● alewa mai launuka biyu masu kama da gummy

● Alewar Cola mai ɗanɗano

● alewa mai kama da na dala

● alewa mai ɗanɗanon pear

● alewa mai siffar donut

● Wake mai jelly

Matsalolin da Aka Fi Sani a Samar da Gummy Candy

Babban ƙalubale a samar da alewar gummy shine bin ƙa'idodi na musamman; in ba haka ba, ba za a iya cimma yanayin da ake so da ɗanɗanon ba. Kula da zafin jiki shi ma abin damuwa ne, domin duk wani bambancin zafin jiki zai iya shafar ingancin samfur da daidaito kai tsaye. Bugu da ƙari, rashin aiki na kayan aiki, rashin inganci, ko gazawar na iya haifar da jinkiri wajen samarwa ko rashin daidaiton girma da siffar samfurin. Bugu da ƙari, dole ne a bi matakan tsafta da aminci, domin haɗarin gurɓatawa na iya yin illa ga ingancin samfur, musamman idan aka bi ƙa'idodin da ke kula da samar da abinci da kayan ƙanshi. Don magance waɗannan matsalolin, kulawa da kyau, kula da kayan aiki, da bin ƙa'idodin aiki na yau da kullun suna da mahimmanci don tabbatar da daidaito da inganci na samar da alewar gummy.

Fa'idodin Injin Samar da Candy na Gummy

Sayen sabuwar fasahar samar da alewa ta gummy yana ba da fa'idodi da yawa, kamar inganta ingancin aiki da ingancin samfura. Da farko, waɗannan tsarin suna ba da babban matakin sarrafa kansa, wanda ke rage aikin hannu da inganta amincin tsari. Bugu da ƙari, suna kula da iko kan mahimman sigogin aiki, kamar zafin jiki, danko, da saurin motsawa, yana tabbatar da daidaiton ingancin samfur.

1. Ingantaccen Inganci & Fitarwa: Layukan atomatik na iya samar da guda 8,000 zuwa 768,000 a kowace awa, dangane da samfurin da kuma tsarin.

2. Ingancin Samfura Mai Daidaito: Tsarin sarrafa kansa yana tabbatar da cikakken iko akan sinadaran, zafin jiki, da lokaci, wanda ke haifar da daidaiton laushi, siffa, da dandano a kowane tsari.

3. Tanadin Kuɗi: Rage farashin aiki saboda sarrafa kansa na ciyarwa, ajiya, gyare-gyare, da kuma rushewar hanyoyin.

4. Tsaron Abinci da Tsafta: Bakin ƙarfe, gina abinci, da sarrafa kansa yana rage hulɗar ɗan adam, yana rage haɗarin gurɓatawa.

5. Tallafi ga Gummies na Nutraceutical & Specialty: Yana da ikon samar da gummies masu mayar da hankali kan lafiya (misali, bitamin, vegan, ba tare da sukari ba) tare da takamaiman allurai da sinadaran da aka sanya a cikin lakabin.

Ƙara ci gaban kasuwancinku tare da kayan aikin samar da gummies

Idan kuna la'akari da injinan samar da gummies don kasuwancin ku, tabbatar kun nemi sabbin injuna, masu inganci, kuma masu iya daidaitawa don bazara. Manyan majiyoyin masana'antu sun nuna cewa haɗa abubuwan da ke cikin tsarin atomatik, kamar injinan girki da adanawa akai-akai, na iya inganta hanyoyin samarwa. Hakanan ana iya amfani da tsarin gudanar da dijital don sarrafa zafin jiki da auna adadin sinadaran, tabbatar da inganci da daidaito na alewa masu laushi da injinan ke samarwa. Hanyoyin saita samarwa masu sassauƙa suna sauƙaƙa saurin amsawa ga canje-canje a cikin buƙata da tayin samfura. Waɗannan jarin fasaha ba wai kawai suna rage yawan samarwa ba har ma suna taimaka wa kamfanoni su ci gaba da yin gasa a cikin kasuwa mai saurin canzawa.

Nemo Mai Kaya Mai Inganci Don Fara Kasuwancin Gummy Candy ɗinku!

Tun daga shekarar 1989, mun ƙware a fannin samar da sitaci. Muna samar da mafita iri ɗaya tun daga girkin alewa mai laushi zuwa ƙira. Zuwa yanzu, Yinrich ta yi nasarar samar da kayan alewa masu laushi, kayan marufi na alewa masu laushi, da sauran nau'ikan kayan alewa ga abokan ciniki a ƙasashe da yankuna sama da 60 a duk duniya.

A matsayinta na mai kera layin samar da alewa na duniya , Yinrich tana da kayan aiki sosai don samar da layukan samar da sitaci da shawarwarin samar da kayan da ake buƙata don samar da alewa mai laushi. Don duk wani tambaya, da fatan za a ziyarci gidan yanar gizon mu na layin samar da alewa mai laushi don sabbin bayanai game da samfura da cikakkun mafita. Tuntuɓe mu a yau don yin magana da ƙungiyar ƙwararrunmu ta fasaha.

Tambayoyin da ake yawan yi

T: Waɗanne kayan aiki ake amfani da su a layin samar da alewa mai ɗanɗano?

A: Ana amfani da tankunan hadawa sau da yawa a layin samar da alewa don tauna cingam saboda sauƙin amfaninsu. Ana amfani da su tare da tukunyar dumama don tabbatar da ingantaccen maganin zafi, da kuma mai ajiya (ko mai ajiya da kansa, mai ajiya da alewa) don saka jelly a cikin molds da aka yi da robar silicone. Sannan ana sanyaya molds ɗin ta halitta kafin a rushe su, suna samar da siffar da ake so, kamar beyar, kifi, da sauransu. A ƙarshe, suna ratsawa ta cikin ramin sanyaya sannan a shafa su da mai rufewa.

T: Yaya muhimmancin girke-girken alewa a cikin tsarin kera alewa mai ɗanɗano?

A: Ingancin kowace samfur ya dogara ne da girke-girkensa, haka nan kuma dole ne a sami kyakkyawan girke-girke na alewa, domin yana ƙayyade ɗanɗano, laushi, tsawon lokacin da za a ajiye shi, da sauran fannoni. Saboda haka, girke-girke mai kyau na ƙara dandano yana tabbatar da daidaiton sinadaran, daidaito, da riƙe da danshi, wanda ke haifar da laushi da laushi da ake buƙata don samar da beyar gummy ko wasu alewa masu inganci.

T: Menene fa'idodin amfani da injin yin alewa na gummy ta atomatik?

A: Amfani da injin yin alewa na gummy ta atomatik yana ba da fa'idodi da yawa, gami da ingantaccen samarwa, ingancin alewa na gummy daidai gwargwado, da ƙarancin kuɗin aiki. Wannan yana ɗaya daga cikin ingantattun dabarun yin fudge mai yawa, saboda injunan galibi suna da sarrafawa da sarrafa su ta atomatik daidai gwargwado.

QUICK LINKS

Kayan Aikin Yinrich na Kayan Ƙamshi

CONTACT US

Mai ƙera Kayan Kayan Ƙamshi na Yinrich