Gummy Candy Production Line Ultimate Guide:Discover How to Made Gummy Bears

Gummy candies have long been a favorite among candy lovers for their soft texture and vibrant colors. This article will explain the specific machines and production lines used in gummy candy production, as well as the types of gummy candy production lines required for different gummy candies. It will uncover the secrets of gummy candy manufacturing and the workings of gummy candy production lines. Innovative gummy candy production machinery can produce innovative gummy candy shapes and flavors, kick-starting your gummy candy business!

Gummy Candy's Popularity in the Market

Gummy candies are widely considered a convenient and delicious snack that not only satisfies sweet cravings but also provides a boost of energy and a pleasant taste. Gummy candies are a popular trend, especially among teenagers.

In the market, various brands and manufacturers offer a variety of gummy candies in various flavors, shapes, and formulations to meet the needs of diverse consumers. Some companies have also introduced functional gummy candies, such as those with added vitamins, fiber, and other healthy ingredients, as well as customized gummy candies.

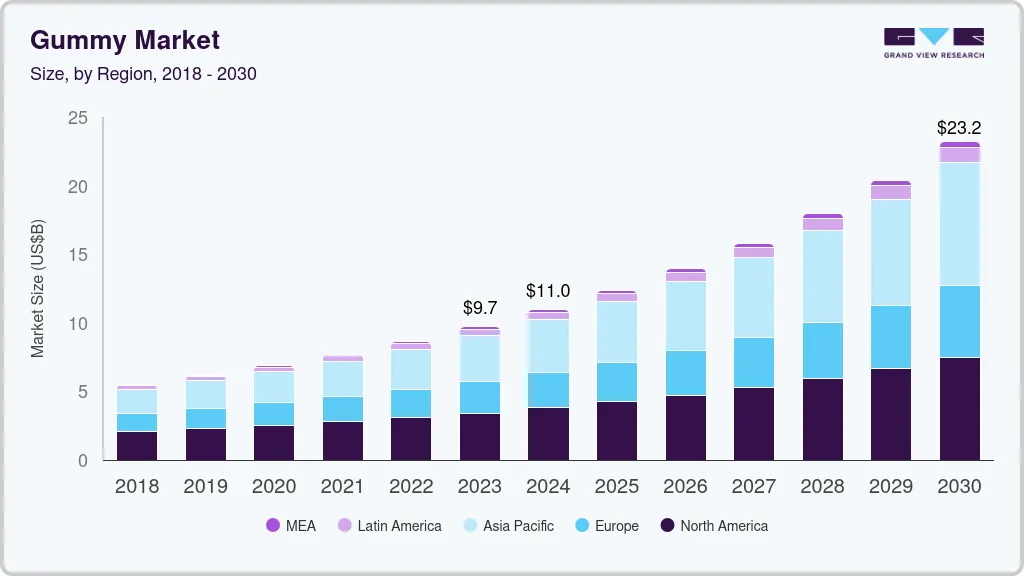

As a small snack, gummy candies are not only popular among children, but are also enjoyed by young people and adults. Gummy candies come in a variety of flavors and shapes, along with attractive packaging designs, appealing to consumers of all ages. Furthermore, with increasing awareness of health and nutrition, low-sugar and sugar-free gummy candy brands are gaining popularity, further expanding the market. The global gummy candy market was valued at $23 billion in 2024 and is projected to grow at a compound annual growth rate of over 10.4% from 2025 to 2034. The global gummy candy market is experiencing a rise in functional gummy candies, offering health benefits far beyond those of traditional candies.

Best-Selling Gummy Bears

Gummy bears have carved a niche in society with their captivating taste, texture, and nostalgic appeal. Gummy bears first appeared in Germany in the 1980s, and within a century, they have gained immense popularity and recognition worldwide. Their chewy texture provides a wonderful sensory experience, while their fruity flavor makes them appealing to children and adults alike. Popular brands like Haribo have helped elevate gummy bears to mainstream popularity. As a result, they are able to deliver just the right taste and feel, making gummy bears the perfect sweet fruit candy.

What is the Jelly candy production process like?

Machines used to mass-produce gummy candies typically follow a process similar to the following:

Preparation: Ingredients, such as pectin or gelatin, water, sugar, flavorings, and colorings, are prepared and measured according to the desired recipe.

Mixing: The ingredients are combined in a large mixing vessel or tank. The mixture is heated and stirred to dissolve the sugar and activate the gelling agent (pectin or gelatin). Flavorings and colorings are added at this stage.

Cooking: The mixture is heated to a specific temperature to ensure proper gelatinization of the gelling agent. This step promotes the formation of a gel-like structure in the gummy candy.

Conditioning and Cooling: After cooking, the mixture is allowed to cool to the appropriate temperature. During this stage, the gummy candy mixture is conditioned, which helps achieve the desired texture and consistency.

Forming: The gummy candy mixture is then fed into a machine called a depositor. A depositor typically consists of a series of nozzles or molds used to dispense the gummy candy mixture into specific shapes, such as bears, worms, or fruit. This machine ensures that the gummy candy mixture is accurately dispensed into the molds.

Cooling and Setting: Once the gummy candy mixture is deposited into the molds, it is transferred to a cooling tunnel or conveyor belt. This allows the candies to cool and solidify, allowing them to hold their shape.

Demolding and Inspection: After the candies have completely solidified and cooled, they are removed from the mold. This can be done manually or with the help of an automated demolding machine. The candies are then inspected for quality control, checking for any defects or flaws.

These steps may vary depending on the specific equipment and processes used by different manufacturers. However, the overall goal is to efficiently produce large quantities of candies while maintaining consistent quality and shape.

How does Jelly Candy Production Line work?

The core task of a candy production line is to automatically transform raw materials such as sugar, glue, water, and flavors/colorings into candies with a uniform shape, a pliable texture, and a stable shelf life. The entire process can be thought of as six major steps: ingredients → boiling → flavoring and coloring → pouring → cooling and shaping → demolding → drying. These steps are centrally controlled by a PLC and run continuously or intermittently.

Ingredients and Pretreatment

Solids (such as sugar, syrup, gelatin/pectin/carrageenan, and starch) are fed into a weighing hopper via vacuum suction or an elevator. The formula is transmitted from the MES to the PLC, with an error of ≤±0.5%.

Colloids must be pre-soaked: they must swell in pure water at 60–70°C for 20–30 minutes, followed by a "solution" step at 85–90°C for 20 minutes to completely open the colloids and reduce the viscosity peak at the rear end. Otherwise, a "tail" or "stringiness" will appear during pouring.

Sugar Boiling

The sugar and water are first heated in a sugar dissolving pot to 106–108°C, reaching a solubility of approximately 75%. The sugar is then pumped into a continuous vacuum thin-film sugar boiling machine (or vacuum cooking tank) for flash evaporation at 105–115°C under a vacuum of 0.6–0.8 bar. This process reduces the moisture content to 12%–14% over 3–5 minutes, preventing browning at high temperatures while maintaining a viscosity of 1200–1800 mPa·s for subsequent pouring.

The vacuum process also removes tiny bubbles, enhancing the transparency of the soft candy. A steam condensation recovery system converts the secondary steam into 80°C hot water that is returned to the boiler, saving approximately 30% energy.

Online Flavoring, Coloring, and Acidification

The cooked sugar gelatin solution enters the "static mixer + online flavoring/acidification" module. Flavoring, coloring, citric acid/malic acid, and functional ingredients (vitamins, probiotics, etc.) are injected via servo metering pumps at a ratio of 0.1%–1%. The mixing time is <10 seconds to prevent localized excessive acidity from causing pre-coagulation of the gelatin.

Pouring and Molding

The servo pouring head acts as the "metronome" for the entire production line. It uses a gear pump or plunger pump to inject 85–90°C sugar syrup into the mold with an accuracy of ±1%.

Cooling and Preliminary Shaping

The mold enters a cooling tunnel at 10–15°C via a chain conveyor. Air pressure is 0.8–1.2 kPa, cooling the sugar temperature to 25°C within 30 minutes. The gelatin network begins to form an elastic skeleton, and the water activity (Aw) drops to 0.65–0.70, preventing the sugar from sticking to the mold.

Demolding and Conveying

Starch molds: Twist and vibrate 180°, depositing the soft candy into the downstream vibrating screen for sugar and powder separation; starch is rotary dried at 60°C and screened through a 60-mesh screen for reuse, with a loss of less than 2%.

Gummy Candy Production Line Types – Overview

Gummy Candy Depositing Lines

Soft candy depositing lines operate continuously during large-scale manufacturing processes and are therefore fully automated. They help improve efficiency while reducing labor costs because they do not require an operator to be present at all times, unlike other types that require frequent checks after a certain period of time.

● Production Capacity: 150–2000 kg/h

● Advantages: High output rate; consistent quality; low labor requirements

● Applications: Production of gelatin/pectin soft candies, two-color/filled soft candies, and functional soft candies

Gummy Candy Filling Lines

The complete soft candy filling line consists of a batch jelly cooking system, an FCA (flavor, color, and acid) batching and mixing system, a multi-purpose candy depositor, a cooling tunnel, and a sugar or oil coating machine. ● Production Capacity: 200–800 kg/h

● Advantages: High precision; easy scalability; minimal material waste during production

● Applications: Production of filled gummy candies, popping vitamin gummy candies, jelly gummy candies, and spherical gummy candies

Jelly Candy Starch Molding Line

The starch mold depositing machine is primarily used to produce starch gummy candies. The entire line includes boiling, molding, automatic powder application, depositing (capable of filling, left-right dual-color depositing, or top-down dual-color depositing according to customer requirements), powdered sugar separation, and powder recovery systems.

● Production Capacity: 200–800 kg/h

● Advantages: High precision; easy scalability; minimal material waste during production

● Applications: Production of sour sand gummy candies

Jelly Mogul Line

The Jelly Mogul Line is an advanced, fully automated gummy candy production line. It delivers high quality, easy operation, stable performance, and high output. The entire line includes a kitchen system, molding line, starch conditioning system, starch collection and recovery system, finished product finishing, and supporting systems.

● Production Capacity: 400–1500 kg/h

● Advantages: Syrup flow rate is precisely controlled by a variable frequency control system, ensuring stability.

● Applications: Suitable for producing starch-based soft candies, gelatin, carrageenan, mixed gums, and other soft candies.

3D Mold Jelly Candy Production Line

The 3D Jelly Candy Depositing Line is a soft candy depositing machine that uses blister molds. It is designed for producing soft candies with complex shapes and designs. It uses a rotating mold to achieve intricate and intricate shapes.

● Production Capacity: 400–1500 kg/h

● Advantages: Syrup flow rate is precisely controlled by a variable frequency control system, ensuring stability.

● Applications: 3D soft candies such as eyeballs, gummy bears, fruit candies, and cartoon-shaped candies.

What types of gummy candies can the gummy candy machine make?

You can use our jelly candy production line to produce a variety of jelly candies: gummy bears, jelly candies, pectin candies, carrageenan beans, etc:

● Heart-shaped gummy candies

● Jelly ball gummy candies

● Bar gummy candies

● Gummy bears

● Double-layer gummy candies

● Cola gummy candies

● Pyramid gummy candies

● Prickly pear gummy candies

● Donut-shaped gummy candies

● Jelly beans

Common Problems in Gummy Candy Production

A major challenge in gummy candy production is strictly adhering to specific recipes; otherwise, the desired texture and taste may not be achieved. Temperature control is also a concern, as any temperature variations can directly impact product quality and uniformity. Furthermore, equipment malfunction, inefficiency, or failure can lead to production delays or uneven product size and shape. Furthermore, hygiene and safety measures must be adhered to, as the risk of contamination can compromise product quality, particularly in compliance with laws governing food and confectionery manufacturing. To address these issues, careful supervision, equipment maintenance, and adherence to standard operating procedures are essential to ensure consistent and high-quality gummy candy production.

Benefits of Gummy Candy Production Machinery

Purchasing new gummy candy production technology offers numerous advantages, such as improved operational efficiency and product quality. Firstly, these systems offer a higher degree of automation, which reduces manual labor and improves process reliability. Furthermore, they maintain control over key operating parameters, such as temperature, viscosity, and stirring speed, ensuring consistent product quality.

1. High Efficiency & Output:Automated lines can produce 8,000 to 768,000 pieces per hour, depending on the model and configuration.

2. Consistent Product Quality:Automated systems ensure precise control over ingredients, temperature, and timing, resulting in uniform texture, shape, and flavor in every batch.

3. Cost Savings:Reduced labor costs due to automation of feeding, depositing, molding, and demolding processes.

4. Food Safety & Hygiene:Stainless steel, food-grade construction, and automated handling minimize human contact, reducing contamination risks.

5. Support for Nutraceutical & Specialty Gummies:Capable of producing health-focused gummies (e.g., vitamin, vegan, sugar-free) with precise dosing and clean-label ingredients.

Boost your business growth with gummies production equipment

When considering gummies production machinery for your business, be sure to look for new, efficient, and scalable machines for the summer. Leading industry sources indicate that integrating essences into automated systems, such as continuous cooking and depositing machines, can improve production processes. Digital management systems can also be used to control temperature and measure ingredient quantities, ensuring the quality and uniformity of the soft candies produced by the machines. Flexible production setup methods facilitate rapid response to changes in demand and product offerings. These technological investments not only reduce production volumes but also help companies remain competitive in a rapidly changing market.

Find Reliable Supplier to Start Your Gummy Candy Business!

Since 1989, we have specialized in starch production lines. We provide one-stop solutions from soft candy cooking to molding. To date, Yinrich has successfully supplied soft candy equipment, soft candy packaging equipment, and other types of candy machinery to customers in over 60 countries and regions worldwide.

As a world-class candy production line manufacturer, Yinrich is well-equipped to provide the starch production lines and production advice needed for soft candy production. For any inquiries, please visit our soft candy production line website for the latest product information and complete solutions. Contact us today to speak with our professional technical team.

FAQs

Q: What equipment is used in a gummy candy production line?

A: Mixing tanks are often used in candy production lines for chewing gum because of their versatility. They are used in conjunction with a heating kettle to ensure proper boiling heat treatment, and a depositor (or the depositor itself, the candy depositor) to deposit the jelly into molds made of silicone rubber. The molds are then naturally cooled before being demolded, forming the desired shape, such as a bear, fish, etc. Finally, they pass through a cooling tunnel and are then coated using a coater.

Q: How important is the candy recipe in the gummy candy manufacturing process?

A: The quality of any product depends on its recipe, and so too must a good candy recipe, as it determines taste, texture, shelf life, and other aspects. Therefore, an ideal sweetening recipe ensures the correct ingredient stability, uniformity, and moisture retention, resulting in the soft, springy texture required to produce high-quality gummy bears or other candies.

Q: What are the benefits of using an automatic gummy candy making machine?

A: Using an automatic gummy candy making machine offers many advantages, including higher production efficiency, consistent gummy candy quality, and lower labor costs. This is one of the most reliable techniques for making large quantities of fudge, as the machines typically have very precise controls and automation.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer