A Basic Introduction Of Gummy Candy Machine

Gummy candy is a kind of elastic candy that is loved by people. It is popular for its unique taste and colourful shapes. In the process of gummy candy production, the gummy candy machine plays a vital role. gummy candy machines are also usually equipped with automated control systems that can accurately adjust various process parameters to ensure stable product quality. Advanced gummy candy machine models also have high production capacity and can meet the needs of mass production. In general, the gummy candy machine is an indispensable key equipment for gummy candy manufacturing and an important guarantee for candy companies to improve production efficiency and ensure product quality.

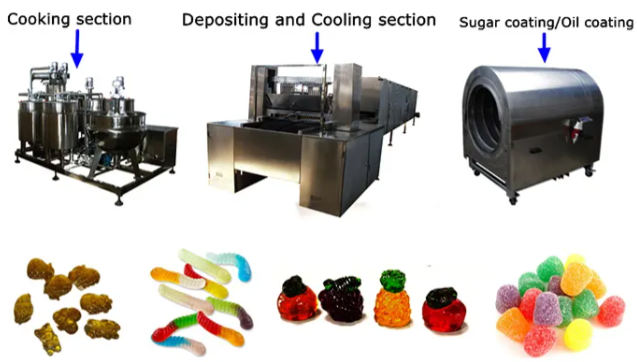

The gummy candy machine is a mechanical equipment specially used for gummy candy manufacturing. It mainly consists of the following parts:

Candy Refining Pot

The production of gummy candy requires boiling the soft syrup syrup first. The candy refining pot adopts constant temperature heating technology to ensure precise control of the slurry temperature and fully stir the mixed raw materials.

Forming Mold

The soft syrup is poured into a special mold and formed. The mold designs are diverse and can produce gummy products of various shapes and sizes.

Cooling System

The formed gummy candy needs to be quickly cooled and set to maintain the shape and taste of the product. The advanced fudge machine is equipped with an efficient cooling system.

Release System

After cooling is complete, the fondant needs to be removed from the mould. The gummy production machine is equipped with a special demoulding device that can automatically complete this process.

The process of the gummy candy production line is usually as follows:

Boil Candy

The first step in making fudge is mixing the ingredients. This usually involves heating a mixture of candy, corn syrup, gelatin, flavourings, and other ingredients in a large whisk until it reaches a syrup-like consistency.

Pouring

Once the mixture is thoroughly mixed and heated, transfer it to a storage container. A reservoir is a machine that drops quantities of mixture onto a conveyor belt or tray.

Cool Down

Then move the fudge to the cooling chamber to let it cool and set. This can take anywhere from a few minutes to a few hours, depending on the size and thickness of the fudge.

Demoulding

When the fondants have cooled and set, remove them from the moulds or trays. This can be done manually or automatically. Depending on the desired texture and shelf life, the fondant can be dried in a drying chamber for several hours. This will help remove excess moisture and prevent the fudge from sticking together.

Here are some important things to remember when making fudge:

1. Make it according to your requirements, including size, temperature and time. Any aspect of the recipe will affect the texture, flavour and consistency of the fudge.

2. Use high-quality ingredients: Use high-quality gelatin, juice or other ingredients to ensure flavour and texture.

3. Mix the ingredients well: It is important to mix the ingredients well to make sure everything is well dispersed and evenly distributed in the mixture.

4. Heat the mixture appropriately: Heat the mixture to the recommended temperature and hold it long enough to melt any gelatin, but avoid overheating, which will destroy the gelatin and affect the texture of the fudge.

5. Use clean equipment: Before starting, make sure all equipment and surfaces are clean and free of any contamination.

6. Allow the fudge to set properly: Allow the fudge to cool and set properly according to the instructions to ensure they have the right texture and consistency.

7. Store gummies: Store gummies in an airtight container and keep at room temperature away from heat and moisture.

When you plan to purchase a candy making machine, many factors must be considered to help produce the candy. Some important factors are highlighted below:

1. Candy Making Machine Size

Check the dimensions below i.e. length, width, height and total weight of the candy machine. Typically, production needs and the size of the candy dictate the size to be used. Usually, the candy making machine is used in conjunction with the candy boiling machine, candy pouring machine and other glue making machines to form a candy making production line.

2. Power Requirements

candy machines generally require enough power to fully operate, and power requirements vary. You have to know the amount of work the candy machine is going to do, as this determines the required power rating. Therefore, you should work with professional candy machine manufacturers and suppliers who will help you choose a candy making machine with the correct power rating to provide a complete candy production solution.

3. Production Capacity

It is important to have a machine that can meet your production needs, taking into account its production capacity and automation level. Therefore, if you want to produce candies on a large scale, you will need a gummy machine with a larger capacity that can also accommodate the raw materials.

4. Operating Conditions

For candy machines, some operating conditions you should be aware of are temperatures measured in degrees Celsius. Additionally, humidity is measured in percentages.

5. Molding Time

Moulding time determines production speed and candy output, which plays a very important role in your production costs and profitability.

Yinrich is a professional confectionery equipment supplier in China, we have been specializing in high quality gummy candy machines for more than 10 years. If you are looking for a mature factory in China, please contact Yinrich Confectionery Machine Supplier!

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer