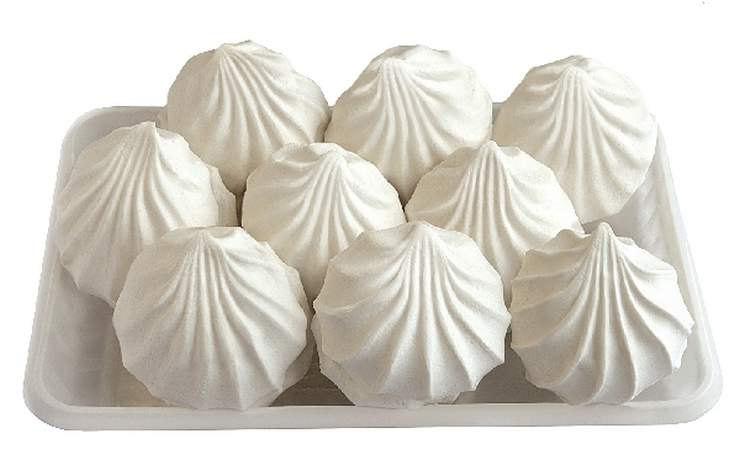

Automatic Complete Deposited Marshmallow production Line

Top hard sugar Confectionery Equipment suppliers. WhatsApp|Wechat: +8613801127507, +8613955966088

Automatic Complete Deposited Marshmallow production Line

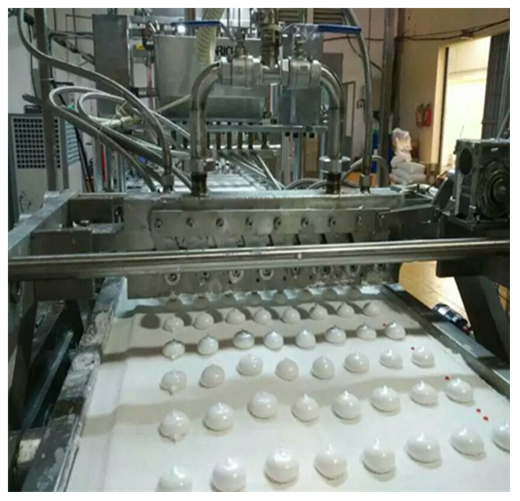

1)In the pre-mixer, all the ingredients to be dissolved and cooked. (An automatic YINRICH ‘s AWS can be used for auto weighing and mixing.).

2)Then the basic slurry is continuously pumped to a cooker till the final moisture level is reached.

3)After cooking, the slurry will be cooled.

4)Then the cooled “marshmallow base” is passed through the continuous aerator.

5)The product then be divided and injection with different colors and flavors.

6)The multi-color product is extruded ,and transported on a cooling conveyor for cooling down;

7)The conditioned marshmallows are dusted top and bottom with starch, or a mixture of both starch and icing sugar in a separate dust cabin; the product is cut to the required length here.

8)The dust cabin is kept under a strict control to prevent the “dust” spreading throughout the plant. The excess starch/sugar is removed.

9)Optional: The final is transferred to a chocolate enrobing machine for coating its surface with chocolate.

10)The coated products under cool down;

11)The final products are transferred to a packaging machine.

| Model | JEM120 |

| Production capacity kg/h | 120~200 |

| Making size of the product mm | Dia.20~40mm |

Steam consumption kg/h Steam pressure MPa | 150 0.2~0.6 |

| Electric power needed | 35kW/380V |

Compressed air consumption Compressed air pressure | 1.5mP3P/min 0.6-0.8MPa |

Conditions needed for the cooling system:

| 20~25 45~55 |

| Gross weight kgs | 12000 |

| Total length of the line m | 35 |

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer