Cylinder shape extruded marshmallow production line with a big capacity of 450~500kg/h

we have different marshmallow manufacturing equipment that can meet different customers' requirements.

It can change extruding nozzles to change the shapes.

Top hard sugar Confectionery Equipment suppliers. WhatsApp|Wechat: +8613801127507, +8613955966088

Cylinder shape extruded marshmallow production line with a big capacity of 450~500kg/h

we have different marshmallow manufacturing equipment that can meet different customers' requirements.

It can change extruding nozzles to change the shapes.

The EM500 Extruded Marshmallow Line is a high-capacity, fully automated marshmallow production system designed for industrial use. With an output of 450~500 kg/h, this extruded marshmallow machine is ideal for large-scale manufacturers looking to produce consistently high-quality marshmallows in various shapes, colors, and flavors. The line supports multi-color extrusion, twisted shapes, and center-filled options, making it perfect for OEM and private-label confectionery businesses.

This extruded marshmallow line can produce a wide range of marshmallow types, including:

● Single-color marshmallow ropes

● Multi-color twisted marshmallows

● Center-filled marshmallows (jam, chocolate, cream)

● Animal or flower-shaped marshmallows (via custom dies)

● Mini marshmallows for cereal or hot chocolate

● Sugar-free or functional marshmallows (with recipe adjustment)

Raw Material Cooking System

This system is responsible for cooking and preparing the raw materials needed for marshmallow production. It ensures that ingredients such as sugar, water, corn syrup, and gelatin are properly heated and mixed to create the marshmallow mixture.

Forming System

The forming system forms the marshmallow mixture into the desired shape, such as cubes, cylinders, or custom designs. It utilizes various devices, such as dies or extruders, to achieve a consistent, uniform marshmallow shape. The process begins by depositing a thick layer of anti-sticking starch or glucose onto a conveyor belt. The marshmallows are then extruded onto this thick starch layer.

Marshmallow Dryer

After marshmallows are formed, they need to go through a drying process to remove excess moisture and achieve the desired texture. Automated drying lines are typically equipped with conveyor belts or dedicated drying chambers to achieve efficient drying while maintaining product quality.

A complete EM500 extruded marshmallow line typically includes the following components:

Automatic Ingredient Dosing & Mixing System – Precise mixing of sugar, glucose, gelatin, and water

Continuous Cooker – Maintains optimal temperature and moisture levels

Cooling Unit – Rapid cooling of the marshmallow slurry

High-Speed Aerator – Introduces air for fluffy texture

Color & Flavor Injection System – For multi-color and multi-flavor products

Extrusion Unit – Shapes the marshmallow into ropes or custom profiles

Starch Coating & Dusting System – Prevents sticking and ensures clean cutting

Cutting Machine (Guillotine Type) – Cuts marshmallow ropes into desired lengths

Cooling Conveyor – Stabilizes product before packaging

Automatic Packaging System (Optional) – Integrated flow wrapper or carton packing

High-Quality Marshmallow Production Equipment

This marshmallow production line is designed to produce marshmallows in a variety of shapes and fillings, with a production capacity of up to 500 kg/hour. To meet quality and food hygiene standards, the line utilizes high-sensitivity Siemens sensors and is constructed from brushed stainless steel.

The marshmallows can be extruded or cast to suit your needs. For more information about our marshmallow making machines, please contact us today.

QUICK LINKS

CONTACT US

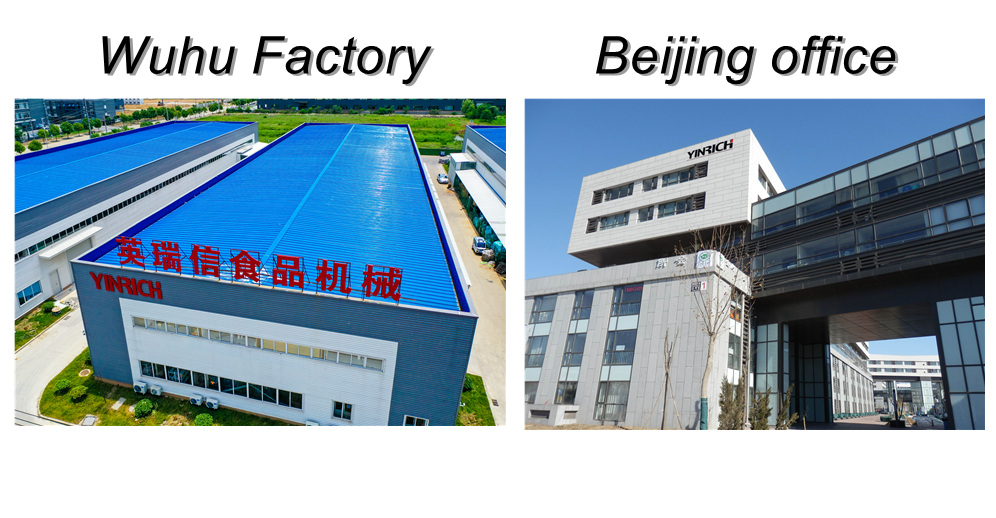

Yinrich Confectionery Equipment Manufacturer