Complete Guide To Gummy Candy Manufacturing: How To Produce Gummy Candy At Scale

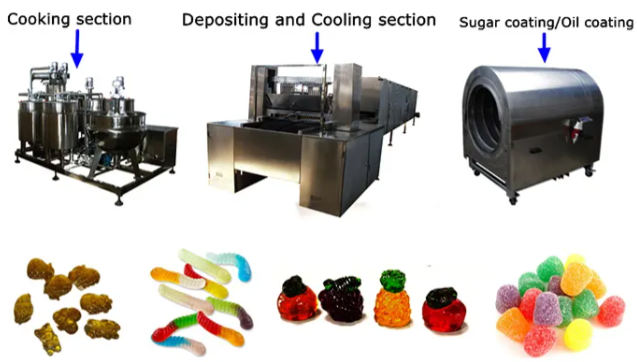

There are some key components that must be in place for large-scale gummy candy production. Mixing tanks are probably the most important of these, as they allow for precise mixing of ingredients during the gummy candy production process. Subsequently, a cooking system is needed to heat and cook the mixture to the correct viscosity. Depositors and molds are then used to precisely shape the gummies, after which they pass through a cooling tunnel to achieve their final shape. Conveyors are then also needed to move the gummies from one station to another. In addition, these rotary fillers for gluing machines are essential for gluing different styles and packages of different sizes. Quality control systems, including metal detectors and various automatic inspection equipment, ensure the product safety required throughout the manufacturing process. Each machine has its specific features that help improve the efficiency, uniformity, and quality of the gummy candy production line.

What types of gummies can be produced on a large scale?

On a commercial scale, a wide variety of gummy candy varieties can be produced. For example, gummy bears, fruit-shaped gummies, sour gummies, and vitamin or supplement gummies are common among many people. You can also produce pectin gummies for the vegetarian or vegan market. Another booming market is functional gummies, such as gummies with added CBD or other beneficial ingredients. The texture properties of the soft candy can also be modified so that softer, chewier or harder soft candies can be made.

What are the key steps in the soft candy batch manufacturing process?

The soft candy manufacturing process starts with making the soft candy base, which usually includes gelatin, sweeteners and flavorings. The gelatinous mixture is poured into a heating machine and stirred during the heating process. The liquid soft candy mixture is then formed into specific shapes with the help of a soft candy depositing machine. After that, the soft candy mass is poured into the shape, cooled, and moved into the mold after the cooling stage. Therefore, millions of soft candy masses can be easily manufactured in this way.

Understanding the soft candy machine

The soft candy machine is a very complex equipment that combines advanced technology to complete a variety of soft candy production and automation processes. It includes mixing, heating and depositing, which helps to minimize the workflow as well as the intensity of manual labor. Usually, the machine consists of a large-capacity mixing chamber that controls the temperature over time to ensure the correct proportions of the soft candy base. It also has a depositing section that automatically pushes the mixture to the boundaries for precise shaping. When it comes to complex soft candy machines, some are designed with in-line cooling tunnels and inspection systems to increase production and quality. The individual integration of these processes enables uniform production quality; therefore, the soft candy machine is considered an essential piece of equipment for automated production systems.

Choosing the Right Soft Candy Depositor

The selection of a suitable soft candy depositor should take into account production capacity, precision, and integration with existing equipment. Such production and output should be met in conjunction with production line specifications. This is very important for maintaining volume consistency and shape of the produced product. In addition, the compatibility, ease of use, and maintenance of the depositor with other equipment must be considered for efficient use and increased productivity. Further improvements may include setting machine parameters according to product type and having the ability to quickly switch between operating modes. These will certainly help improve the flexibility and efficiency of the production system.

Soft Candy Production Line Production Steps

● Formulation and Preparation: The first stage involves preparing the soft candy frame by mixing gelatin, sweeteners, flavorings, colorants, and other excipients in a specific ratio. This mixture is heated until a precise and uniform mass is obtained. This uniform mass is the basis for melting the soft candy.

● Poting Process: After the soft candy base is formed, it is fed into the prepared mold using a pouring instrument. This step is essential for determining the shape and size of the soft candy. Depositors use either continuous or batch processes depending on the desired production volume.

● Cooling: Now, the set gummies are cooled in a controlled environment. The molds are placed in a cooling tunnel and the temperature is allowed to gradually drop. This controlled temperature helps the gummies ingredients in the molds to solidify and harden.

● Demolding and Coating: After the gummies ingredients have cooled, the gummies are removed from the molds. Other ingredients like oil or sugar can be rolled onto these gummies to enhance their taste and prevent them from sticking to the gummies.

● Packaging: The final step is to sort and package the gummies for sale. Modern packaging procedures effectively preserve the gummies and extend their shelf life while adhering to strict labeling standards and safety measures.

How do I choose the right gummies making equipment for my production needs?

A: To determine which gummies making equipment is best for you, you must consider your projected production volume, the kinds of gummies products you intend to produce, and the available locations. Start by evaluating what you want to make (gummy bears per hour or in a day). You can also research proprietary gummy bears and compare the specifications of their equipment. It is also important to check the auxiliary equipment supplied with the machine, as the maintenance and after-sales service required will often depend on these. However, it is often very beneficial to seek advice from a professional confectionery maker: they usually also know the equipment supplier, so it is quite confident that a firm decision can be made based on this knowledge and experience.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer