Chocolate Lentil Forming Line: High Quality, Easy Operation

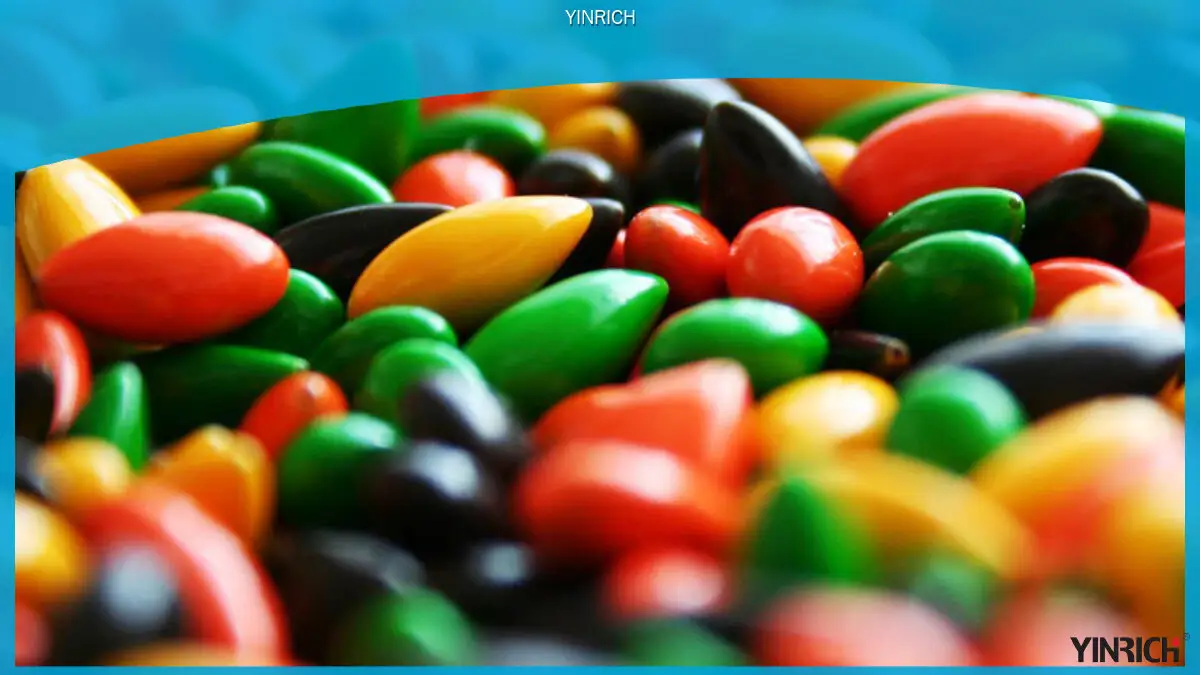

This chocolate lentil molding machine is dedicated to chocolate molding. It can be used for cooling and molding pure chocolate beans of various shapes, including spherical, oval, lentil, etc. It is easy to operate, hygienic and safe, and is an ideal choice for producing high-quality chocolate beans.

Application:

QD series Chocolate Lentil Production Line is used to make the chocolate centers that are most often subsequently coated with sugar and colorants. These centers can take on several forms, such as lentils, balls, coffee beans or almonds.

Product advantages

Our Chocolate Lentil Forming Line offers high quality and precision in product creation, ensuring consistent and delicious results every time. With easy operation and user-friendly controls, this machine allows for efficient production without the need for complicated training. The line boasts features such as customizable forming options, adjustable speed settings, and durable construction for long-lasting performance.

Team strength

Team strength is at the heart of our Chocolate Lentil Forming Line. Our skilled and dedicated team ensures that each machine is of the highest quality and operates smoothly. With years of experience in the industry, our team is able to provide training and support to ensure easy operation for our customers. By working together, our team is able to innovate and improve our products constantly, making sure that we deliver the best solutions for our clients. Choose our Chocolate Lentil Forming Line for a seamless production process and the assurance of a strong and reliable team behind it.

Why choose us

When it comes to our Chocolate Lentil Forming Line, our team strength lies in our commitment to high quality and easy operation. Our dedicated team of experts works tirelessly to ensure that every aspect of our product is top-notch, from the quality of the chocolate used to the efficiency of the production process. With a focus on teamwork and collaboration, we are able to deliver a machine that not only meets but exceeds expectations. Our collective experience and passion for excellence drive us to constantly innovate and improve, making our Chocolate Lentil Forming Line the ideal choice for businesses looking for a reliable and user-friendly solution.

Chocolate lentil molding machine is one of the essential equipment in chocolate processing, equipped with a main console and electric pressure controller for pressure increase and pressure reduction. The machine is equipped with an independent extraction device, and the conveying end is equipped with a sampling valve and an exhaust valve. The machine can produce high-quality milk chocolate, dark chocolate, white chocolate, praline, truffle chocolate, compound chocolate and many other products.

| Model | QD600/2 |

| Capacity(kgs/h) | 100~300(based on the individual weight) |

| Diameter of the roller | 318mm |

| Length of the roller | 610mm |

| Numbers of the roller: | 2sets |

| Max. rotating speed of the roller | 1.5r/min |

| Max. temperature of refrigerator | -30~-28C |

| Forming temperature | -24C~-22C |

| Power of cooling fan in the tunnel | 5HP |

| Power of refrigerator | 17.13kw(15HP) |

| Main drive Power(kw) | 5.9kw |

| Total power of storage tank | 8kw |

| Volume of the storage tank | 300L |

| Dimension(LxWxH)mm | 10803 x2020x2731mm |

| Weight(Kgs) | Appr. 5000kgs |

Working principle of chocolate lentil molding machine

The heated and melted liquid chocolate is distributed into the mold through the material conveying and distribution system, and then the chocolate paste is molded in the groove through the die pressing and the low temperature operation of the mold. Finally, the molded chocolate lentils are pushed out and conveyed to the cooling channel by the conveyor belt for further molding.

What are the main components of the chocolate lentil molding machine?

The chocolate bean molding machine mainly includes cold rollers, conveying systems, cooling systems, cooling systems, separators and other parts.

What are the technical characteristics of the chocolate lentil molding machine?

1. The machine can be equipped with single-head or double-head casting, and can produce different product shapes or color varieties according to your needs.

2. The degree of automation is high. From material conveying, molding to demolding and conveying, the whole process can be continuously and automatically operated with high production efficiency.

3. This chocolate lentil molding machine uses an efficient and energy-saving motor. Compared with similar equipment, it is superior in terms of running speed, working noise, energy saving, etc.

4. The chocolate beans are produced in a fully enclosed environment. The equipment uses food-grade materials, which is easy to clean and meets hygiene standards.

5. It has a precise temperature control system that can accurately adjust the mold temperature so that the chocolate can be quickly solidified and fixed at the appropriate temperature to ensure the stability of product quality.

6. Equipment with different voltages and capacities can be customized according to your requirements.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer