Yinrich Technology has developed to be a professional manufacturer and reliable supplier of high-quality products. Throughout the whole production process, we strictly implement the ISO quality management system control. Since established, we always adhere to independent innovation, scientific management, and continuous improvement, and provide high-quality services to meet and even exceed customers' requirements. We guarantee our new product jelly candy depositing line will bring you a lot of benefits. We are always standby to receive your inquiry. jelly candy depositing line Yinrich Technology have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Latest jelly candy depositing line company, or would like to partner up, we'd love to hear from you.The company keeps up with the development trend of the industry and introduces foreign advanced production equipment and manufacturing technology to improve and innovate jelly candy depositing line. Stable, excellent quality, energy saving and environmental protection.

The fully automatic 4D double-layer jelly candy casting production line can produce high-quality single-color jelly candies, double-color jelly candies, two-layer jelly candies, 3D fruit jelly candies, and 4D three-color sandwich jelly candies. The soft candy pouring production line consists of a sugar dissolving tank, a syrup pump, and a storage room. Tanks with filtration systems, vacuum cookers for fudge, buffer tanks, depositing machines with cooling tunnels. There are 2 chillers at the top of the cooling tunnel to ensure the best cooling effect.

A:Auto-weighing ,dissolving system

This consist of Gelatin dissolving tank ,

Gelatin dissolving tank ,Gelatin transporting pump

Hot water tank and water pump system for providing the hot water to keep warm for tanks

Sugar hopper & elevator

Weighing vessel (for automatic weighing water, sugar, glucose, gelatin solution)

mixing tank ,Discharge pump

All the connecting pipes, valves, frame, and etc,automatic PLC control system

B:Flavor, color, acid dosing and mixing system

This part consist of Flavor liquid storage tank and dosing pump

Color liquid storage tank and dosing pump

Citric acid storage tank and dosing pump

Dynamic mixer

All the connecting pipes,valves,frame

![Custom jelly candy depositing line company Manufacturer | Yinrich Technology 8]()

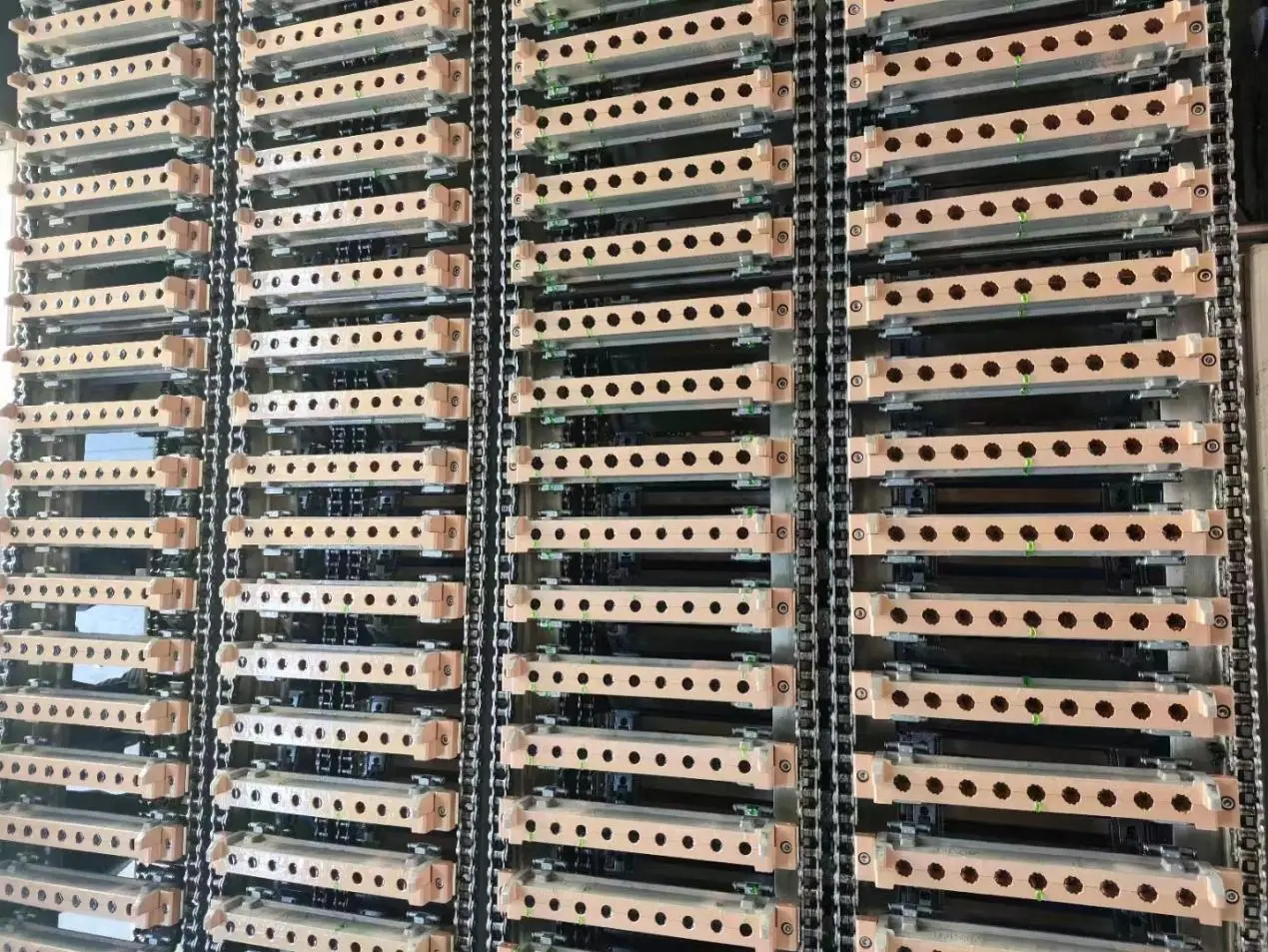

C:Depositing and cooling section

This part consist of Jelly candy Depositor ,Main drive and Mould carrier conveyor,Air-conditioner, and fan system,Discharge conveyor,De-moulding device,Cooling tunnel,PLC control system,Mould oil sprayer system

E :Final products treatment system

Double layer jelly candy depositing line can make candy’s surface with humidification feeling and make a preparation for the next stage (to be coated with sugar granules) after the whirlpool jet ejector through a device which can filter and separate steam and water. So it can enable the sugar to be adhered on the surface of candies.