\

66 Available Coupons

Application

This machine is suitable for full automatic packing round bar products, puffed food etc.

Production work flow : rotary table feeding--conveying--arranging--pillow type packing

Our Automatic Candy Bar Packaging Machine offers a seamless and efficient way to package candy bars with precision and speed, saving significant time and labor costs. The machine is equipped with advanced technology that ensures accurate weight and seal measurements, guaranteeing consistent quality in packaging every time. With its user-friendly interface and customizable settings, this machine is the perfect solution for increasing productivity and enhancing the overall packaging process.

Introducing our Automatic Candy Bar Packaging Machine, a revolutionary solution for streamlining candy bar production and packaging processes. Our team's strength lies in our unmatched expertise in developing cutting-edge technology that increases efficiency and productivity. With a focus on innovation and teamwork, we have designed a machine that combines advanced automation with user-friendly interface, ensuring seamless operation. Our dedicated team of engineers and technicians have worked tirelessly to create a reliable and durable packaging solution that meets the unique needs of candy bar manufacturers. Trust in our team's strength to elevate your production capabilities and drive success in the confectionery industry.

Team strength is at the heart of our Automatic Candy Bar Packaging Machine. Our dedicated team of engineers, designers, and technicians have worked tirelessly to create a cutting-edge, efficient machine that delivers reliable and consistent packaging for your candy bars. With a deep understanding of the industry and a relentless commitment to innovation, our team has ensured that our machine meets the highest standards of quality and performance. By leveraging our team's collective expertise and collaboration, we have created a product that exceeds expectations and helps streamline your packaging process. Trust in our team's strength to enhance your candy bar packaging experience.

1. Advanced full servo control system with simple transmission structure, low failure rate and smooth running of low noise.

2. It can directly connect the production line, making the feeding, molding, filling and sealing process become automatic and improve production efficiency reduces cost.

3. The control system adopts the high quality electrical components, the touch screen shows, the good machine interface, the operation is simple, intuitive, convenience.

4. With automatic membrane feeding device, it can change the packaging film without stopping and improve the production efficiency.

5. The material belt can realize the no-tool quick disassemble, and it is equipped with a slag trough below the belt to facilitate the maintenance and cleaning and saving time and saving effort.

6. There are automatic packaging automatic detection system, which can realize no empty package, and the packing rate reaches 100%.

The packing product size:

L40-170mm

W 10-60mm

H 8-30mm

Specification

| Model | SW-300A |

| Suitable packing material | OPP, CPP, PETA, Aluminum plating film, Aluminum plastic film, waxed paper, single and double layer heating sealing material |

| Packing speed | 50-800 bags/min |

| Film width | Max.300mm |

| Bag size | L: 40-170mm (The selection range depends on the sample length) |

| W:10-60mm | |

| H:8-30mm | |

| Roll film diameter | Max.380mm |

| Voltage | 380V 50Hz 6kw |

| Machine dimensions | L4800*W1150*H1580MM |

| Weight | 3000kg |

| Remark | It can be equipped with coding device and filling air device |

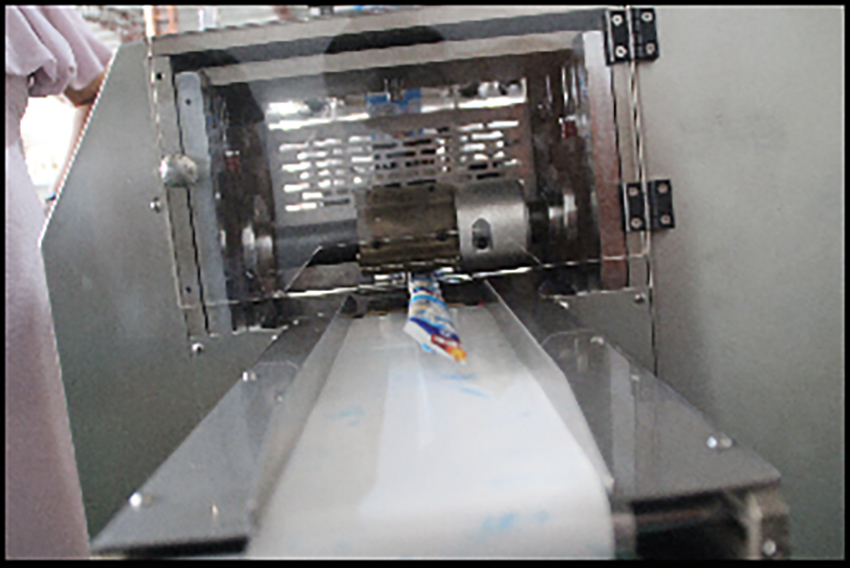

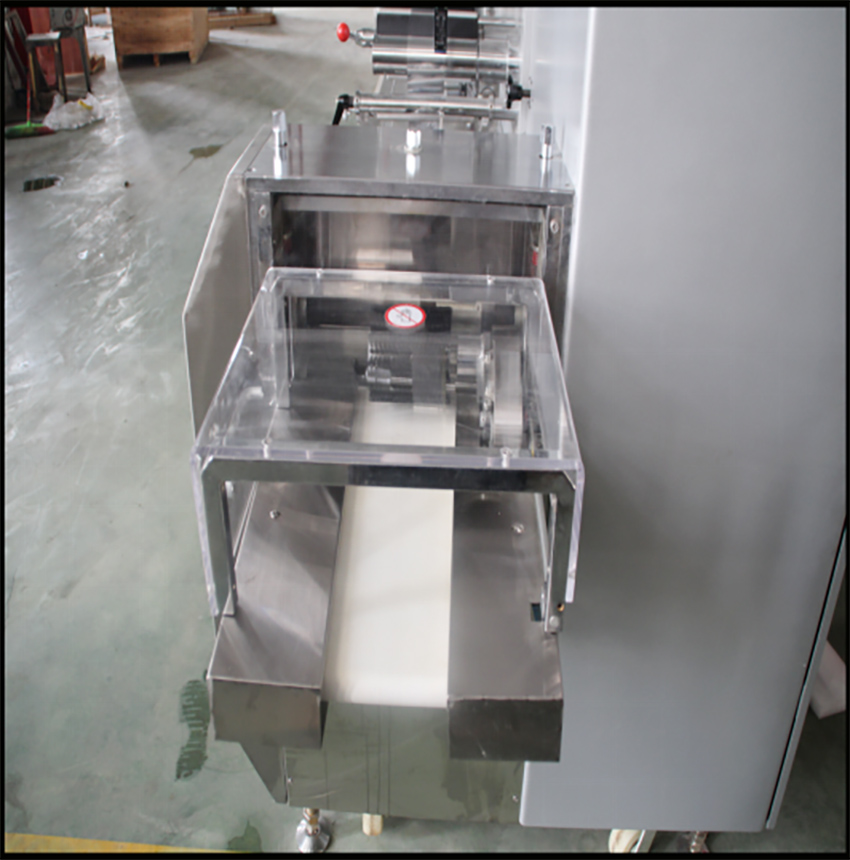

Produce display

● PLC control system, 10 inches screen

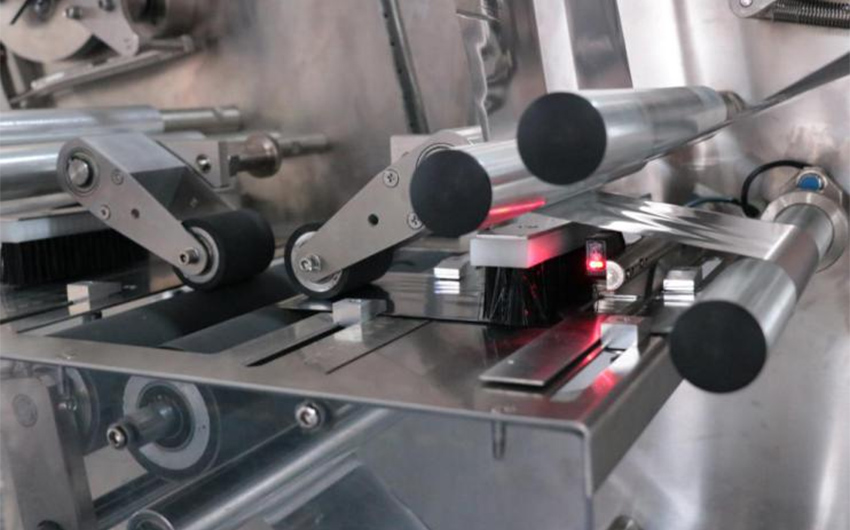

● Three temperature controller, horizontal pre-sealing, horizontal sealing and vertical sealing, to control the sealing precisely, provide the high packing speed, and the beautiful packaging.

● Button, start, jog, stop

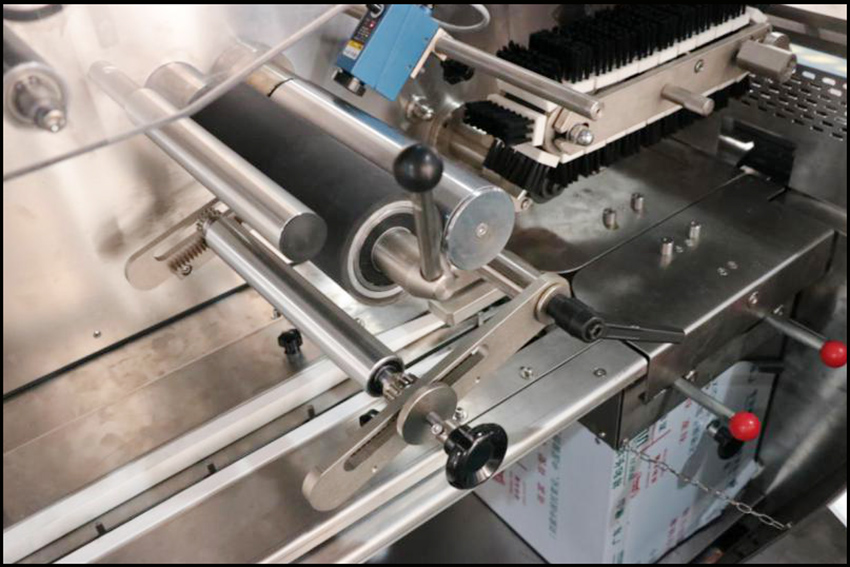

● With double package rollers and can equip paper splicer system, the wrapping package can be used continuously without stopping machine.

● automatic membrane feeding device, it can change the packaging film without stopping and improve the production efficiency.

● There has an servo motor to control the pull film function

● The sensor to confirm if the film is finished

● The eye mark sensor

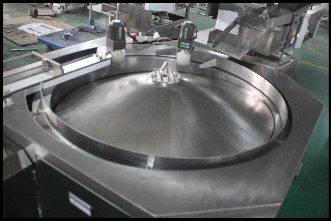

● Adopt the inclined centrifugal disc

● Four frequency converters control the dis speed.

● The advantage about the disc:

A. It would not hurt the material secondly

B. Greatly improve the original nature of packaging materials

C. There would not have the empty bags if the material is enough

D. If there the material is finished in the disc, the disc will be send the signals to machine and stopped at the same time, and notice that the workers need to put some materials

E. If there add the production line, the machine will be able to greatly uninterrupted production packaging

● Oil and broken material hopper

● Oil material's brush

● During the rotating process of the equipment, some oil material will be residues and drops, and the oil or the spice will be fallen down in the material's recycle disc, and the brush will be automatically cleaned to the material outlet

● It is convenient for users to carry out treatment or secondary processing

● With the feeding vibrator, to feeding more evenly

● There has a sensor here to confirm if there has the enough material in the disc

● 6 pieces servo motors to control the belt speed, brand is Panasonic from Japan

● Fiber sensor, to sensor if there has the material here, if no, it will stop and wait the material

● Former, made for the customer according to the material

● There has one servo motor to control the sending materials function

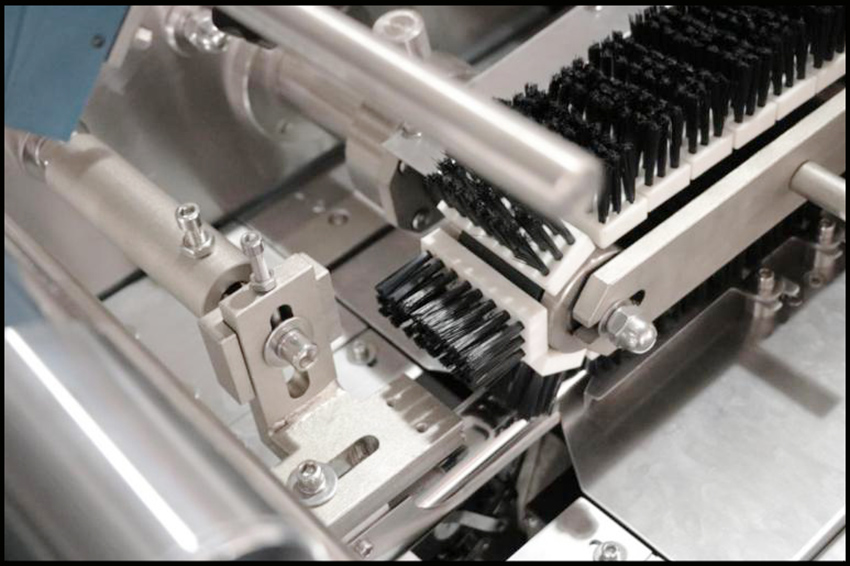

Brush, to flat the packing film, protect the sealing beautiful and flat

● Cutting knife, will according to the sample size, and bag length, the bag length will decided the cutting knife, the cutting knife will decided the packing speed

● Control by the servo motor, to keep the high cutting speed

● Finished product conveyor

● With a PMMA cover

Vacuum cleaning and broken material recycling

● Electric box

● Nine servo motors

● Vibration bucket

● Photoelectric eye control vibration speed, vibration speed is more stable, more uniform feeding, reduce empty bags, can be selected according to customer requirements.

YINRICH® is the leading and professional exporter and manufacturer in China

We providing the high-quality confectionery , chocolate and bakery processing and packaging machinery .

Our factory located in Shanghai ,China. As the top-leading corporation for the chocolate and confectionery equipment in China, YINRICH manufactures and supplies a complete range of equipment for the chocolate and confectionery industry, ranging from single machines to complete turnkey lines, not only the advanced equipment with competitive prices ,but the economical and high efficiency of the whole solution method for the confectionery machines .

\

66 Available Coupons

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer