Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

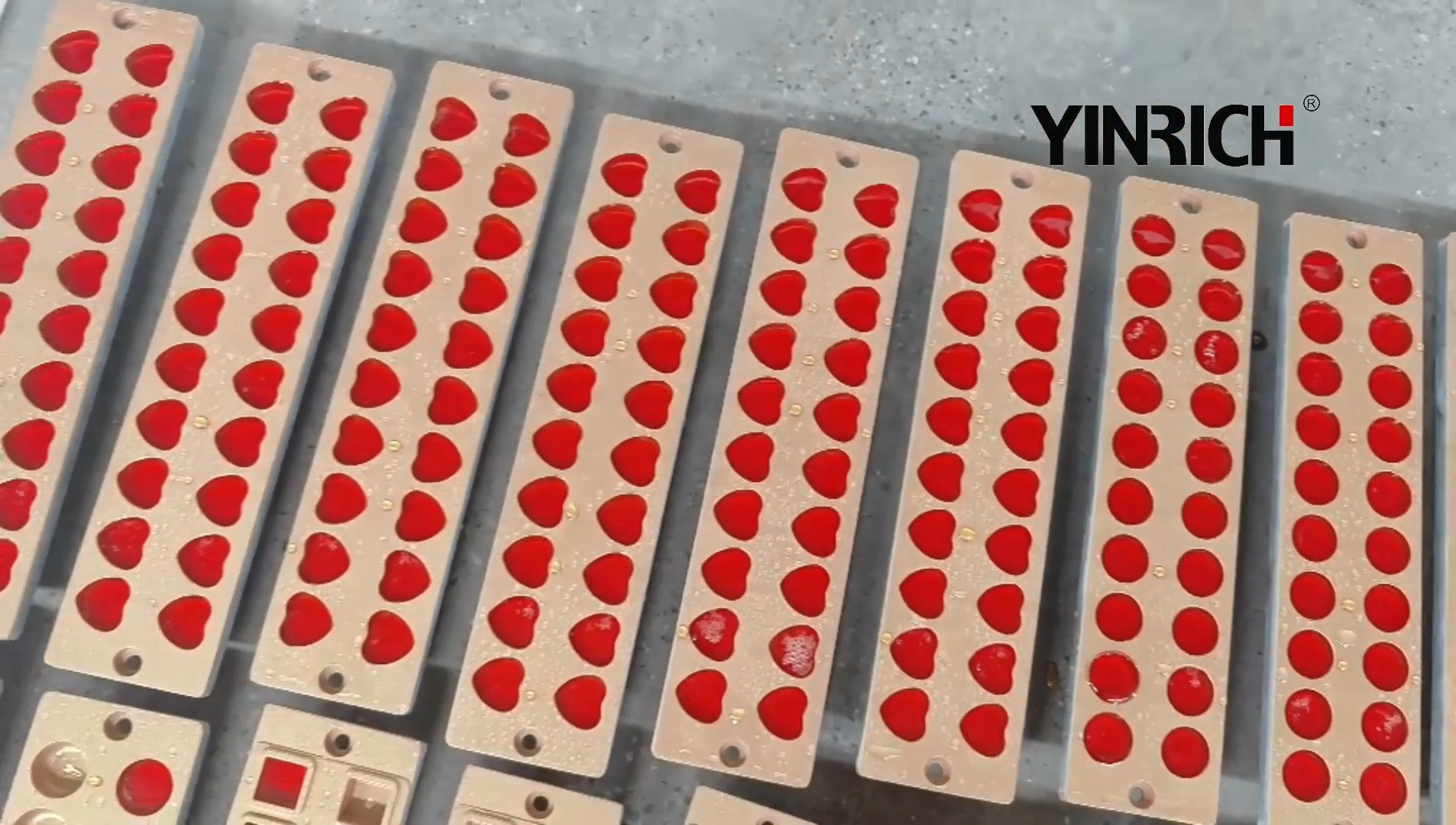

The Yinrich GD30 Lab-Scale Hard & Gummy Candy Depositor is designed for precision and efficiency in small batch production, ensuring consistent quality with its advanced dosing system. Built with durable materials and user-friendly controls, it allows for seamless handling of various candy types, enhancing production flexibility. Key features include adjustable deposit volumes, easy cleaning processes, and a compact design, making it ideal for research, development, and artisanal candy manufacturing.

We serve small to medium-sized confectionery producers by delivering the Yinrich GD30 Lab-Scale Hard & Gummy Candy Depositor, designed specifically for precise, efficient small batch production. Our machine offers reliable, accurate depositing of both hard and gummy candies, ensuring consistent product quality with minimal waste. Built for flexibility and ease of use, it supports innovation and product development at a lab scale, enabling businesses to test and perfect recipes before full-scale manufacturing. With dedicated customer support and tailored solutions, we empower confectioners to streamline their production process, enhance creativity, and bring high-quality candy products to market faster and more efficiently.

We serve small to medium-sized confectionery producers seeking precision and efficiency in candy production. The Yinrich GD30 Lab-Scale Hard & Gummy Candy Depositor is expertly designed for small batch manufacturing, offering reliable, consistent deposition of hard and gummy candies. Our commitment is to provide you with user-friendly equipment that enhances product quality and optimizes production workflows. By combining advanced technology with compact design, we support innovation and flexibility in your candy development process. Whether you are perfecting recipes or scaling up from prototype to production, we serve your business with dependable performance, scalability, and unmatched customer support.

Yinrich hard candy depositing line/ candy depositor

Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

Model: GD30

Output: 50~200KGS/shift

Candy weight:2-6g

Candy colour: one colour and two colour

Control: PLC PLC controls HMI operation

100pcs, one mould 20cavities

100pcs, one mould 10 cavities

Pneumatic type

Remark:

1)All parts which contact the food are made of SUS304;

2)The frame and body cover are made of Stainless steel;

3)Inverters: Danfoss,LG,Delta

4) PLC:SIEMENS

5) Touch screen: SIEMENS

6)Servo motor: TECO

7)Relay: SIEMENS

FREE layout design; FREE assembling and installation; FREE trial-Production and local team training; FREE recipes.But the buyer should be responsible for the round-way air-tickets, local transportation, board & lodging, and USD120.-/Per day/person for the pocket money to our technicians during their stay in the buyer’s site.WANTTANTY

1. The seller guarantee the quality of the machines for 12 months since the date of installation . The seller will supply the 2 years spares for FREE together with the machines;

2. During the warranty period, any problems/defaults happen on the hard parts of the machinery ,the seller will replace the parts or send the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of the buyer, or the buyer needs the technical assistance for the further problems aroused(after the 1st FREE installation), the buyer should be responsible for all our technician’s service cost and their allowance.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer