Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

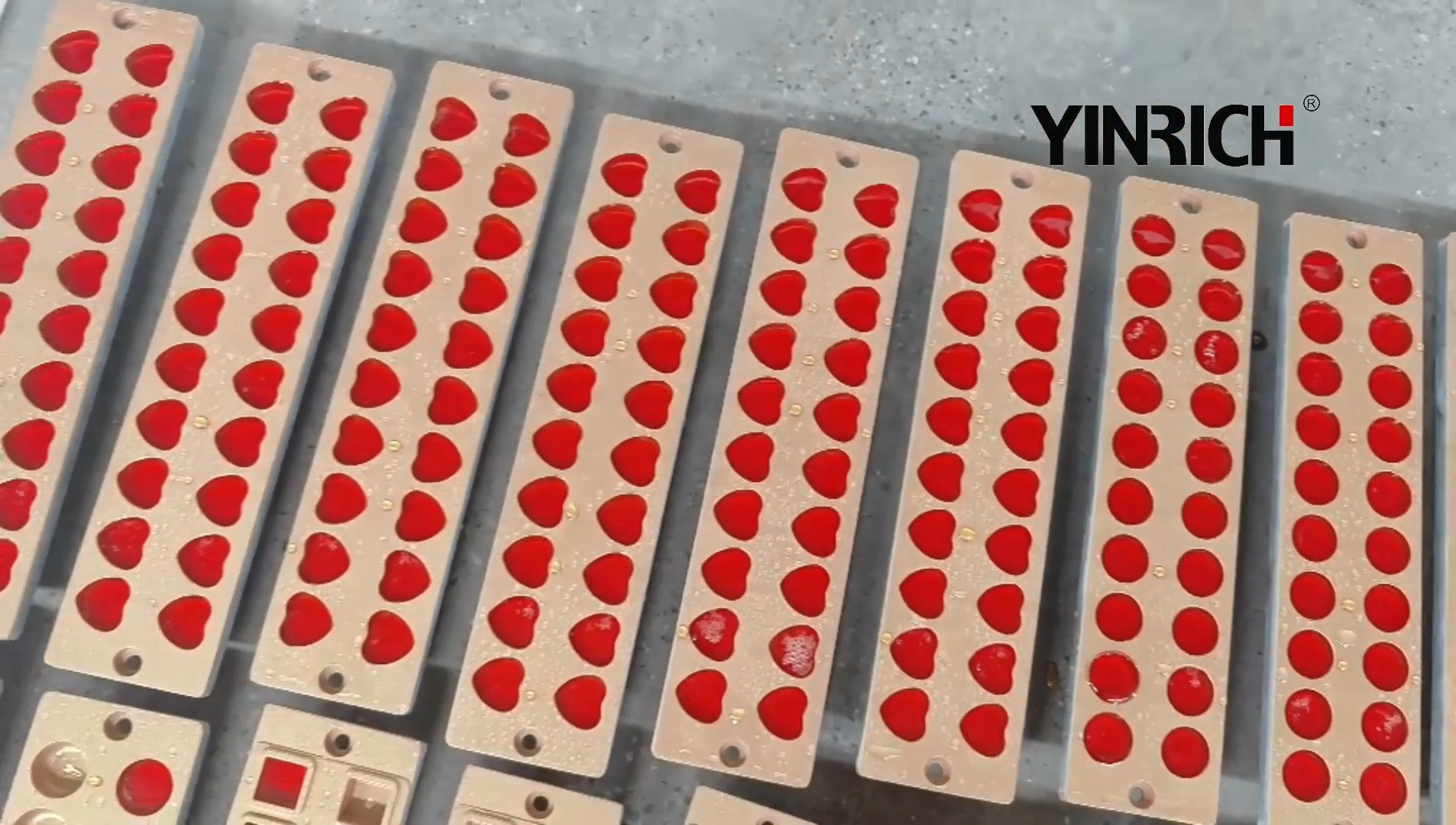

Yinrich GD30 Lab scale gummy candy depositor/ hard candy depositing line for gummy bear-making.

it's a lab machine for small capacity candy making .or can suitable use for shops,change moulds can make different kinds of shapes.

The Yinrich GD30 lab-scale hard candy depositing machine features a robust stainless steel construction with food-grade SUS304 contact parts, ensuring high hygiene and durability for small batch production. Equipped with a PLC-controlled HMI system, servo motors, and customizable candy molds, it offers precise control over candy weight, color, and output capacity ranging from 50 to 200 kg per shift. Its integrated design—including an SS304 sugar dissolving cooker, pneumatic manual de-moulding unit, and efficient agitator—enables consistent, efficient, and customizable hard candy production in a compact footprint.

Our team driving the Yinrich GD30 Lab-Scale Hard Candy Depositor combines decades of industry expertise with innovative engineering to deliver unparalleled reliability for small batch production. Committed to precision and quality, our specialists ensure every machine meets stringent standards, enabling consistent hard candy output with minimal waste. Backed by skilled technicians and responsive customer support, we prioritize seamless integration and user-friendly operation. This dedicated team’s deep knowledge in confectionery technology and manufacturing empowers our customers to scale efficiently while maintaining product excellence, making the GD30 a trusted solution for lab-scale candy production needs.

Our dedicated team behind the Yinrich GD30 Lab-Scale Hard Candy Depositor combines extensive industry expertise with a passion for innovation and precision. With multidisciplinary professionals in engineering, quality control, and customer support, we ensure every unit meets the highest standards of performance and reliability. Our collaborative approach drives continuous product improvement and tailored solutions for small batch production, empowering confectionery businesses to achieve consistent quality and efficiency. Committed to excellence, our team’s deep knowledge and proactive service foster trust and long-term partnerships, making the GD30 an ideal choice for agile, reliable hard candy manufacturing.

Yinrich hard candy depositing line/ candy depositor

Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

Model: GD30

Output: 50~200KGS/shift

Candy weight:2-6g

Candy colour: one colour and two colour

Control: PLC PLC controls HMI operation

100pcs, one mould 20cavities

100pcs, one mould 10 cavities

Pneumatic type

Remark:

1)All parts which contact the food are made of SUS304;

2)The frame and body cover are made of Stainless steel;

3)Inverters: Danfoss,LG,Delta

4) PLC:SIEMENS

5) Touch screen: SIEMENS

6)Servo motor: TECO

7)Relay: SIEMENS

FREE layout design; FREE assembling and installation; FREE trial-Production and local team training; FREE recipes.But the buyer should be responsible for the round-way air-tickets, local transportation, board & lodging, and USD120.-/Per day/person for the pocket money to our technicians during their stay in the buyer’s site.WANTTANTY

1. The seller guarantee the quality of the machines for 12 months since the date of installation . The seller will supply the 2 years spares for FREE together with the machines;

2. During the warranty period, any problems/defaults happen on the hard parts of the machinery ,the seller will replace the parts or send the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of the buyer, or the buyer needs the technical assistance for the further problems aroused(after the 1st FREE installation), the buyer should be responsible for all our technician’s service cost and their allowance.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer