Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

The Yinrich GD30 Hard Candy Depositor is a high-quality piece of equipment designed for efficient candy production. With a candy weight range of 2-6g, this depositor is capable of producing 50-200KGS of candy per shift. Made with SUS304 parts and equipped with PLC controls and HMI operation, this hard candy depositor ensures precise and reliable candy production.

At Yinrich, we serve our customers with the utmost dedication and commitment to quality. Our GD30 Hard Candy Depositor is a versatile and efficient machine that allows you to easily create delicious hard candies with precision and consistency. With its innovative design and user-friendly interface, the GD30 ensures seamless operation and high output capacity. We serve our customers by providing top-of-the-line equipment that meets their needs and exceeds their expectations. Trust Yinrich to deliver superior performance, durability, and reliability, leaving you satisfied with every batch of candies produced. Experience the difference with Yinrich – where we serve with excellence in every detail.

At Yinrich, we serve you by providing top-of-the-line equipment like the GD30 Hard Candy Depositor. Our machine is designed to accurately deposit hot candy mixtures into molds, ensuring consistent and high-quality results every time. With a user-friendly interface and precise control features, this depositor is perfect for small to medium-scale candy production. In addition to its efficiency and reliability, the GD30 also boasts a sturdy construction and easy maintenance, making it a valuable investment for your business. Trust Yinrich to serve you with the best candy depositing solutions on the market.

Yinrich hard candy depositing line/ candy depositor

Specifications

SS304,100L, jacket, tilting type

Electrical heating

With 2 pcs of 30L receive pot

Agitator speed 28rpm

Model: GD30

Output: 50~200KGS/shift

Candy weight:2-6g

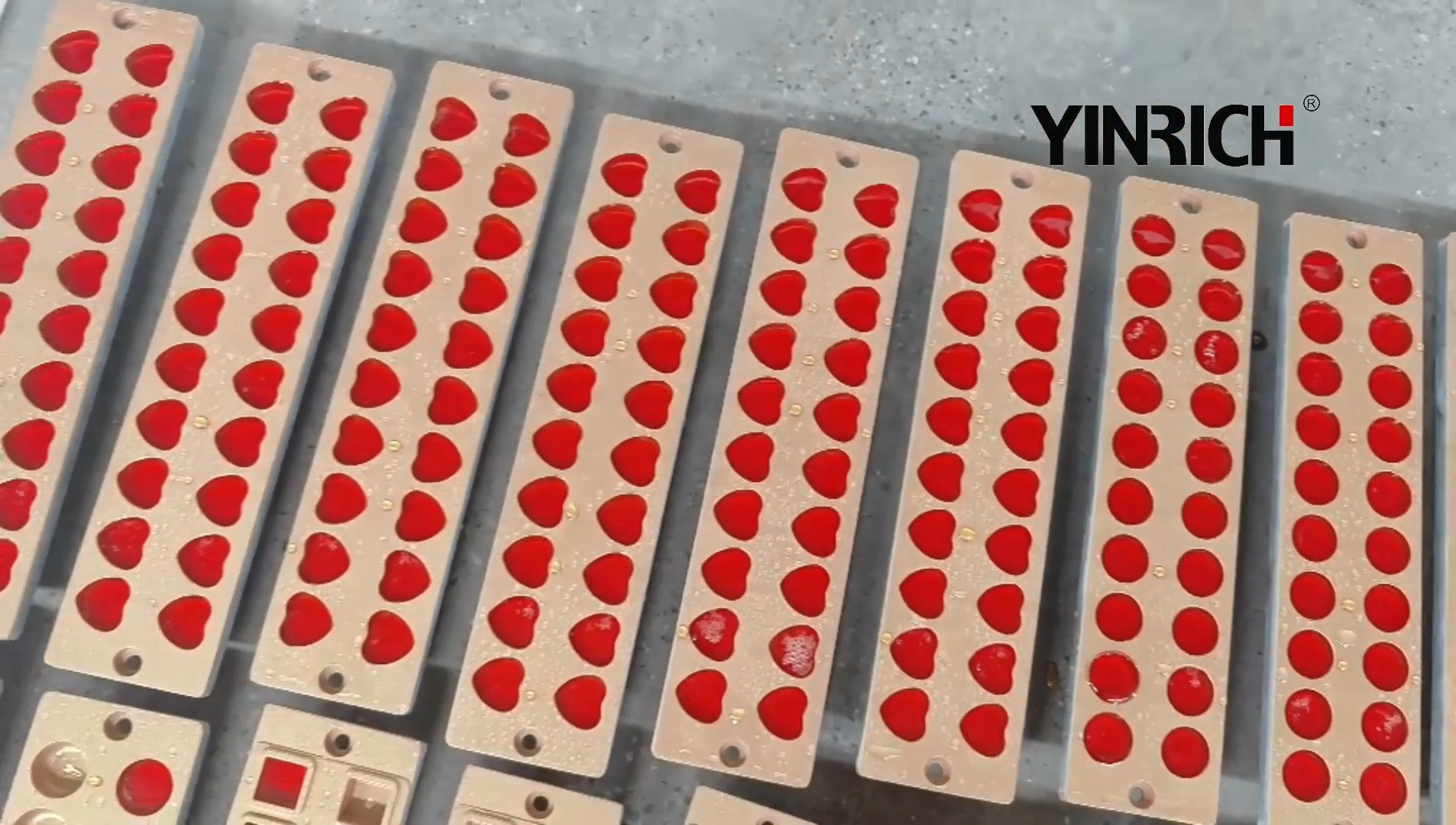

Candy colour: one colour and two colour

Control: PLC PLC controls HMI operation

100pcs, one mould 20cavities

100pcs, one mould 10 cavities

Pneumatic type

Remark:

1)All parts which contact the food are made of SUS304;

2)The frame and body cover are made of Stainless steel;

3)Inverters: Danfoss,LG,Delta

4) PLC:SIEMENS

5) Touch screen: SIEMENS

6)Servo motor: TECO

7)Relay: SIEMENS

FREE layout design; FREE assembling and installation; FREE trial-Production and local team training; FREE recipes.But the buyer should be responsible for the round-way air-tickets, local transportation, board & lodging, and USD120.-/Per day/person for the pocket money to our technicians during their stay in the buyer’s site.WANTTANTY

1. The seller guarantee the quality of the machines for 12 months since the date of installation . The seller will supply the 2 years spares for FREE together with the machines;

2. During the warranty period, any problems/defaults happen on the hard parts of the machinery ,the seller will replace the parts or send the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of the buyer, or the buyer needs the technical assistance for the further problems aroused(after the 1st FREE installation), the buyer should be responsible for all our technician’s service cost and their allowance.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer