Product advantages

Our Jelly Candy Depositing Line with a 500-600kg/h capacity is designed to streamline and automate the process of producing high-quality jelly candies. With precise depositing capabilities, this machine ensures consistent shape and size for each candy, while also offering adjustable settings for customized production. The easy-to-operate interface, durable construction, and reliable performance make this jelly candy depositing line a top choice for confectionery manufacturers looking to increase efficiency and produce delicious sweets.

Company profile

Our company is a leading manufacturer of confectionery equipment, specializing in high-quality jelly candy depositing lines. With a production capacity of 500-600kg/h, our equipment is designed to meet the demands of large-scale candy production while ensuring consistent quality and efficiency. We pride ourselves on our dedication to customer satisfaction, innovation, and continuous improvement. Our team of experts is committed to providing top-notch service and support to help our clients succeed in the competitive confectionery market. Trust us to deliver top-notch equipment that will help you streamline your production process and achieve your business goals effectively.

Enterprise core strength

With a commitment to innovation and quality, our company specializes in providing high-performance equipment for the confectionery industry. Our Jelly Candy Depositing Line boasts a capacity of 500-600kg/h, making it ideal for large-scale production. We prioritize efficiency, reliability, and precision in all our products, ensuring that our customers can meet their production goals with ease. Our team of experts is dedicated to providing exceptional service and support, helping our clients maximize their productivity and achieve success in the competitive market. Trust us to be your partner in confectionery production, delivering top-of-the-line solutions tailored to your needs.

A: Batch-wise cooking system

YINRICH's BJC500 Batch wise jelly mass cooking system offers a feeding, cooking and mixing of raw materials for all type of continuous jelly candy production.

● Full stainless steel SUS304 made;

● Flexible: Design and construction of the cooking and mixing for preparing all types of jelly mass, such as pectin , galantine, agar-agar, starch, gum Arabic, etc.)

● Compact and modular in construction and features central connections for services (steam, air, water, electricity) resulting in a short start-up time.

B: Flavor, color, acid dosing and mixing system

Accurate metering system with plunger type pump driven by a common variable speed unit for the injection of the liquid additives (flavor, color, and acid) The additives are thoroughly mixed into the cooked mass by jacket stainless inline static mixer; In FCA system, it ensures that the end product will always be of a consistent and high quality; Compact design, and fully automatic operation.

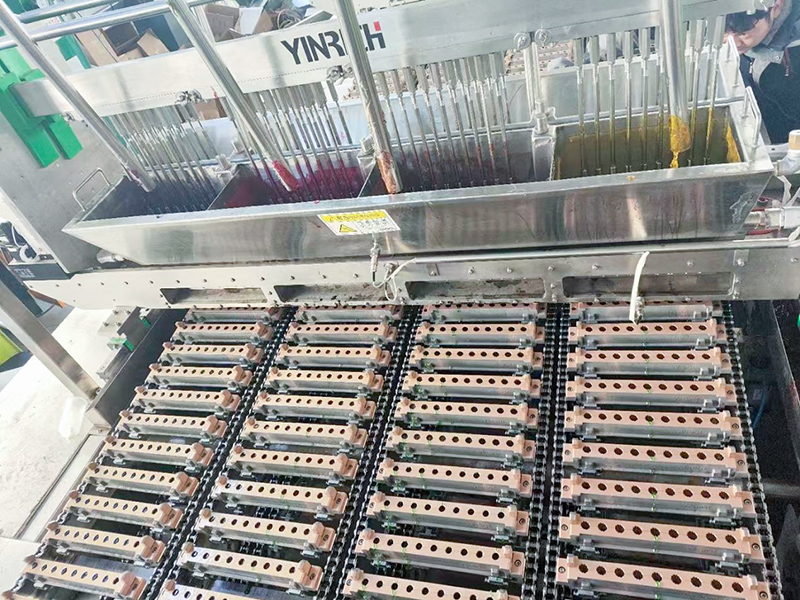

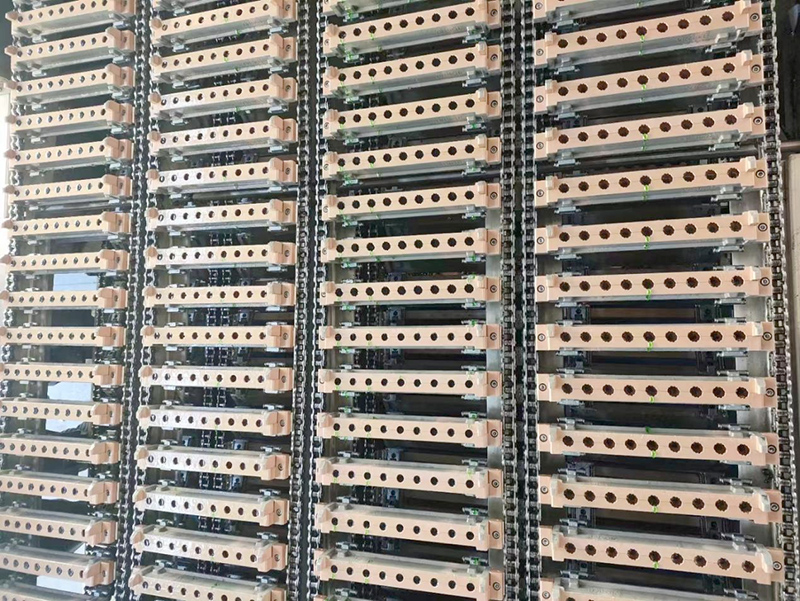

C: Depositing and cooling section

● Underband Servo-drive designed depositer: All drive components are mounted on the machine (underband) rather than on the depositing head.

● The unique design is in compact and simple, which can reduce the movement inertia and weight of the depositing head, thus it can achieve higher the depositor's running speed to maximise output capacity.

● Machine is hydraulic free, thus to avoid risk of oil leakage onto the products.

● Simple maintenance requirement.

● Three axis servo control ensures the complete control over the depositing process.

YINRICH® is the leading and professional exporter and manufacturer in China

We provide high-quality confectionery, chocolate and bakery processing and packaging machinery.

Our factory is located in Shanghai, China. As the top-leading corporation for chocolate and confectionery equipment in China, YINRICH manufactures and supplies a complete range of equipment for the chocolate and confectionery industry, ranging from single machines to complete turnkey lines, not only advanced equipment with competitive prices, but the economical and high efficiency of the whole solution method for the confectionery machines.

![Jelly Candy Depositing Line: 500-600kg/h Capacity 10]()

![Jelly Candy Depositing Line: 500-600kg/h Capacity 11]()

![Jelly Candy Depositing Line: 500-600kg/h Capacity 12]()

![Jelly Candy Depositing Line: 500-600kg/h Capacity 13]()

![Jelly Candy Depositing Line: 500-600kg/h Capacity 14]()

All time technical support after the sales. Relieve your worries

![Jelly Candy Depositing Line: 500-600kg/h Capacity 15]()

High quality control, from Raw material to components chosen

![Jelly Candy Depositing Line: 500-600kg/h Capacity 16]()

12 months warranty since the date of installation.

![Jelly Candy Depositing Line: 500-600kg/h Capacity 17]()

Free recipes ,layout design