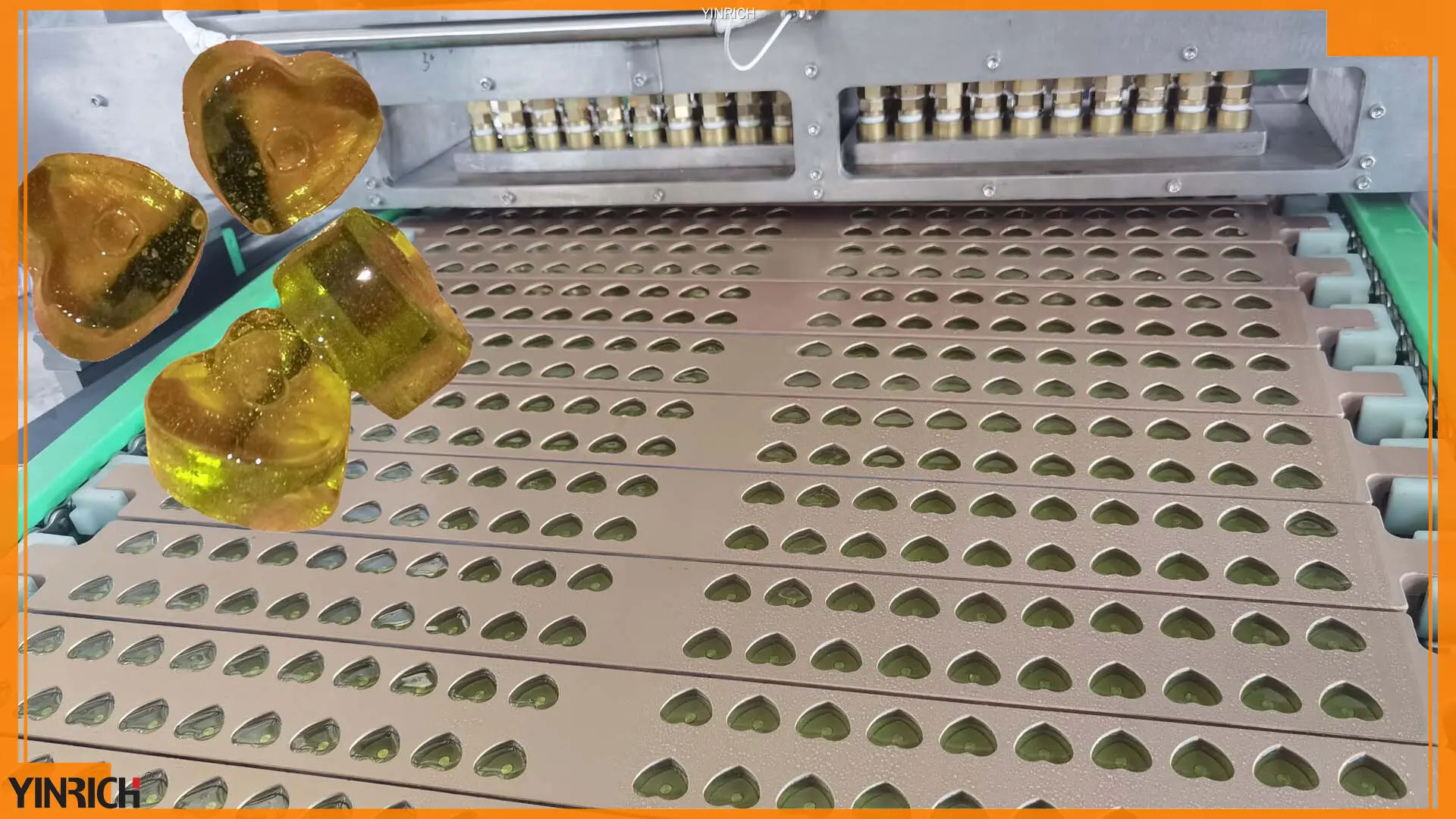

Heart Shape Gummy Candy Production Line - 2022 Factory Price

Product features

The jelly candy making line is a specialized equipment designed for the production of high-grade colloidal candy, including pectin- or gelatin-based gummy candies (QQ candies) in various shapes. With the ability to produce single-color and double-color QQ sugar, this production line can fulfill the quantitative filling and mixing of flavor pigments and acid liquids online. The hygienic structure design not only ensures stable quality but also offers the flexibility to produce poured hard candies by simply changing the mould, making it a versatile and cost-effective solution for confectionery production.

Company profile

With a commitment to quality and innovation, our company specializes in producing heart-shaped gummy candies with our state-of-the-art production line. We strive to offer the finest products at a competitive factory price, ensuring customer satisfaction with every purchase. Our team of dedicated professionals works tirelessly to ensure that each gummy candy meets the highest standards of taste and texture. With a focus on creativity and customer service, we aim to delight consumers of all ages with our delicious and visually appealing candies. Trust us to bring a touch of sweetness to your life with our heart-shaped gummy candy production line.

Enterprise core strength

Our company is a leading manufacturer of high-quality gummy candy production lines, including our latest offering, the Heart Shape Gummy Candy Production Line. With our state-of-the-art technology and expertise in candy manufacturing, we ensure that each machine in our production line is designed for efficiency and precision. Our dedication to innovation and customer satisfaction sets us apart in the industry, as we strive to provide the best equipment at competitive factory prices. Trust in our company for all your gummy candy production needs, and let us help you create delicious treats that will captivate your customers' hearts.

Product Information

GDQ series jelly candy processing line is a production equipment for the production of colloidal soft candy developed according to the special production process requirements of QQ candy. Pectin- or gelatin-based gummy candies (QQ candies) can be continuously produced in various shapes. It is an ideal equipment for producing high-grade colloidal candy. By changing the mould, poured hard candies can also be produced on the same machine. The hygienic structure design can produce single-color and double-color QQ sugar; complete the quantitative filling and mixing of flavor pigments and acid liquids online. Highly automated production can not only produce stable quality, but also save manpower and space to reduce production costs.

Heart Gummy Production Line Process

Different equipment types are needed to ensure gummies you make are of the right quality. These equipment also help to make your work easier and exciting. Listed below are these equipment you will definitely need:

Weighing scale – Needed to ensure all raw materials are measured accurately.

Mixing tank – Here, the mixing tank is needed since all ingredients such as sugar, water, etc will be combined in it.

Cooking pot or vessel – Needed to cook mixed ingredients to an ideal temperature. These vessels mostly come with stirring mechanisms to ensure heating is even and prevent sticking.

Gelatin melting equipment – Used to melt and hydrate gelatin before it is added into the combination or batch.

Deposit equipment – Works by depositing gummy mixture accurately into molds. A depositing machine can be either a manual, semi-automatic, or fully automated system.

Starch Molding trays – These are trays that are filled with cornstarch to have molds created for gummy shaping.

Mold stamping device – To have impressions in starch trays created for gummy mixtures.

Cooling tunnel – To steadily cool and set gummies after depositing into molds.

Demolding equipment – To take set gummies out from molds. Can come in manual or automated systems.

Starch removal equipment – These come in the form of drum sifters or air blowers to get rid of excess starch from gummies.

Wax Coating machine – Used to apply thin layer of carnauba wax or beeswax to gummies.

Polishing drums – Needed to tumble gummies and ensure coating is even and smooth.

Testing instrument – Required for assessing flavor, shelf stability, and texture of gummies.

Product Parameters

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer