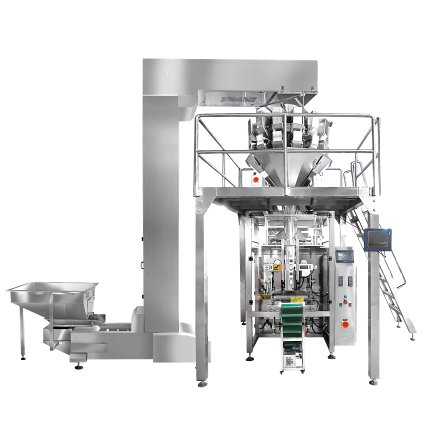

Main Equipment

1.Automatic Vertical form-fill-seal packing machine

2.14 Heads Compact weigher

3.collecting hopper

4.Z type bucket elevator(vibration)

5.Supporting platform

6.bag former

Our Gummies Packing Machine is designed for high-speed production while offering adjustable settings to suit different packaging needs. With its advanced technology, this machine ensures efficient and precise packaging, saving time and labor costs. The compact design and user-friendly interface make it easy to operate, reducing the learning curve for operators.

Team strength is the core foundation of our Gummies Packing Machine. Our highly skilled and dedicated team works together seamlessly to ensure that each machine is crafted with precision and efficiency. With their collective expertise and experience, our team is able to deliver high-speed performance and adjustable capabilities, meeting the diverse needs of our customers. Their commitment to innovation and quality shines through in every aspect of the machine, from its robust construction to its user-friendly interface. Trust in our team's strength to provide you with a reliable and top-notch packing solution for your gummies.

At the heart of our high-speed and adjustable Gummies Packing Machine is a team of dedicated individuals who bring a wealth of experience and expertise to the table. From our skilled engineers who design innovative solutions to our knowledgeable sales and customer service team who provide top-notch support, our collective strength ensures that our machine operates at peak performance. Our team's commitment to excellence and teamwork allows us to deliver a reliable and efficient product that meets the unique needs of our customers. Trust in the power of our team to provide you with a premium packaging solution for your gummies.

Ordinary gummies (such as gummy bears, fruit-flavored gummies)

Functional gummies (vitamins, probiotics, CBD gummies)

Gum-based gummies (bubble gum, chewing gum)

Sugar-coated gummies (coated with sugar or acid powder)

Main Equipment

1.Automatic Vertical form-fill-seal packing machine

2.14 Heads Compact weigher

3.collecting hopper

4.Z type bucket elevator(vibration)

5.Supporting platform

6.bag former

* Famous brand PLC control system, wide version touch screen, convenient to operate..

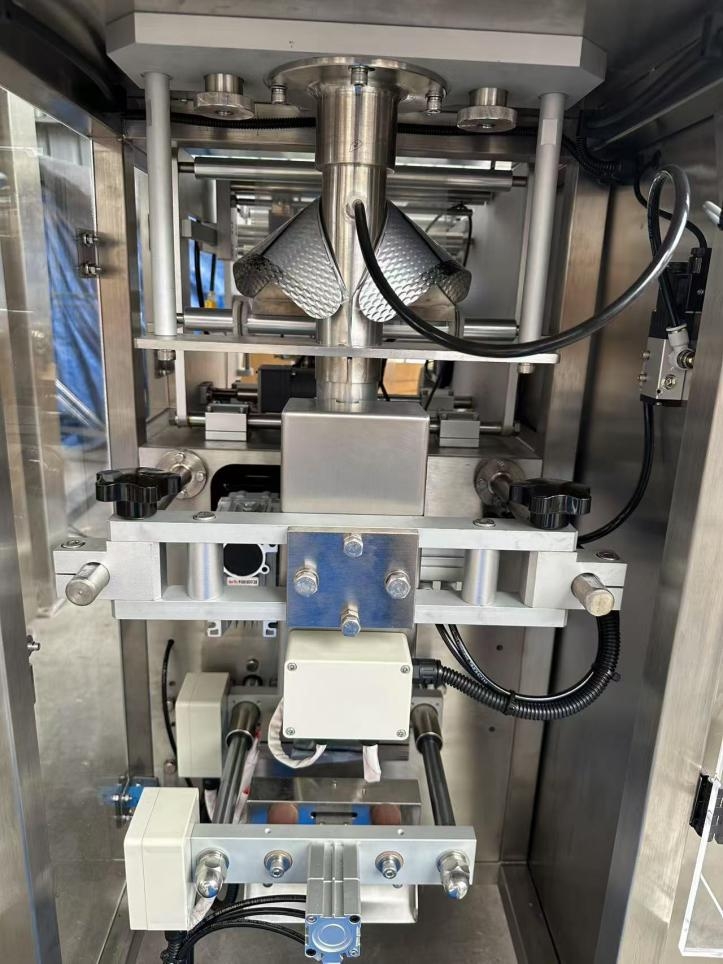

* Film drawing down system and horizontal sealing controlled by servo motor;

* Perfect alarm system to reduce waste;

* It can complete feeding, measuring, filling, sealing, date printing, charging (exhausting), counting, finished product delivery when it equips with feeding and measuring equipment;

* The way of bag making: the machine can make pillow-type bag and standing-bevel bag, punch bag or according to customer’s requirements.

Technical parameter

Technical parameter | Content |

Capacity | 40-60 bag/min |

Bag size | (L)50-200 (W) 60-150mm |

Bag type | Pillow-type bag, standing-bevel bag, punch bag |

Max film width | Max 320mm |

Film thickness | 0.04-0.09mm |

0.04-0.09mm | 0.6Mps 0.25m3/min |

Main power/voltage | 2.2KW/ 220V 50Hz |

Dimension | L1110*W800*H1130mm |

Weight | 350kg |

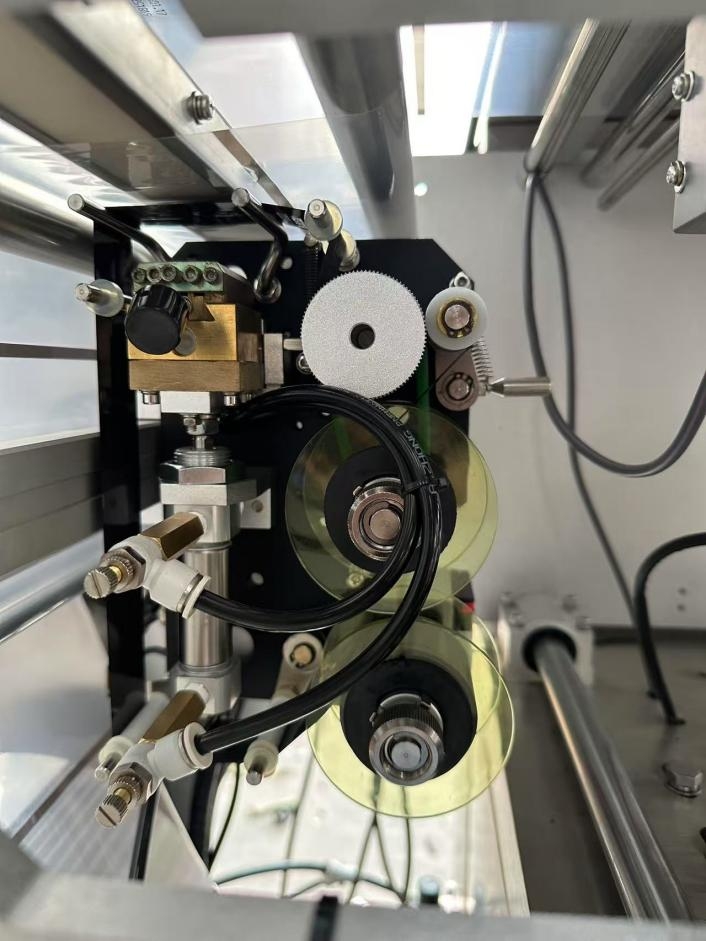

Machine detail photos

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer