Product features

The GDQ600 Double Layer Jelly Candy Depositor is a high-quality and space-saving Jelly Candy Machine that offers fully automatic production of various types of jelly candies, including single-color, double-color, two-layer, 3D fruit, and 4D three-color sandwich jelly candies. Equipped with a sugar dissolving tank, syrup pump, and storage room, along with depositor machines, cooling tunnels, and chillers, this candy casting production line ensures top-notch performance and efficiency. With features like an automatic weighing and dissolving system, flavor, color, and acid dosing system, and a final products treatment system, this machine guarantees consistent and delicious results every time.

Team strength

The GDQ600 Double Layer Jelly Candy Depositor is a high-quality production machine that epitomizes team strength. Our dedicated team worked tirelessly to design a space-saving and efficient jelly candy machine that delivers consistent results. With a strong emphasis on teamwork, we have created a product that is not only reliable but also user-friendly, making it a valuable addition to any production line. Our team's expertise and commitment to excellence shine through in every aspect of the GDQ600, ensuring that it meets the highest standards of quality and performance. Trust in our team's strength to bring you a machine that exceeds expectations.

Enterprise core strength

Team strength is a crucial aspect of the GDQ600 Double Layer Jelly Candy Depositor. Our team of highly skilled engineers and technicians work together to ensure the production of high-quality jelly candies. With years of experience in the industry, our team is able to consistently deliver top-notch results, making this machine a reliable choice for your candy production needs. Additionally, our team is committed to innovation and efficiency, leading to a space-saving design that maximizes production capabilities. Trust in our team's strength to bring you a dependable and efficient jelly candy machine that will take your production to the next level.

The fully automatic 4D double-layer jelly candy casting production line can produce high-quality single-color jelly candies, double-color jelly candies, two-layer jelly candies, 3D fruit jelly candies, and 4D three-color sandwich jelly candies. The soft candy pouring production line consists of a sugar dissolving tank, a syrup pump, and a storage room. Tanks with filtration systems, vacuum cookers for fudge, buffer tanks, depositing machines with cooling tunnels. There are 2 chillers at the top of the cooling tunnel to ensure the best cooling effect.

A:Auto-weighing ,dissolving system

This consist of Gelatin dissolving tank ,

Gelatin dissolving tank ,Gelatin transporting pump

Hot water tank and water pump system for providing the hot water to keep warm for tanks

Sugar hopper & elevator

Weighing vessel (for automatic weighing water, sugar, glucose, gelatin solution)

mixing tank ,Discharge pump

All the connecting pipes, valves, frame, and etc,automatic PLC control system

B:Flavor, color, acid dosing and mixing system

This part consist of Flavor liquid storage tank and dosing pump

Color liquid storage tank and dosing pump

Citric acid storage tank and dosing pump

Dynamic mixer

All the connecting pipes,valves,frame

![GDQ600 Double Layer Jelly Candy Depositor: High-Quality Production, Space-Saving #Jelly Candy Machine 8]()

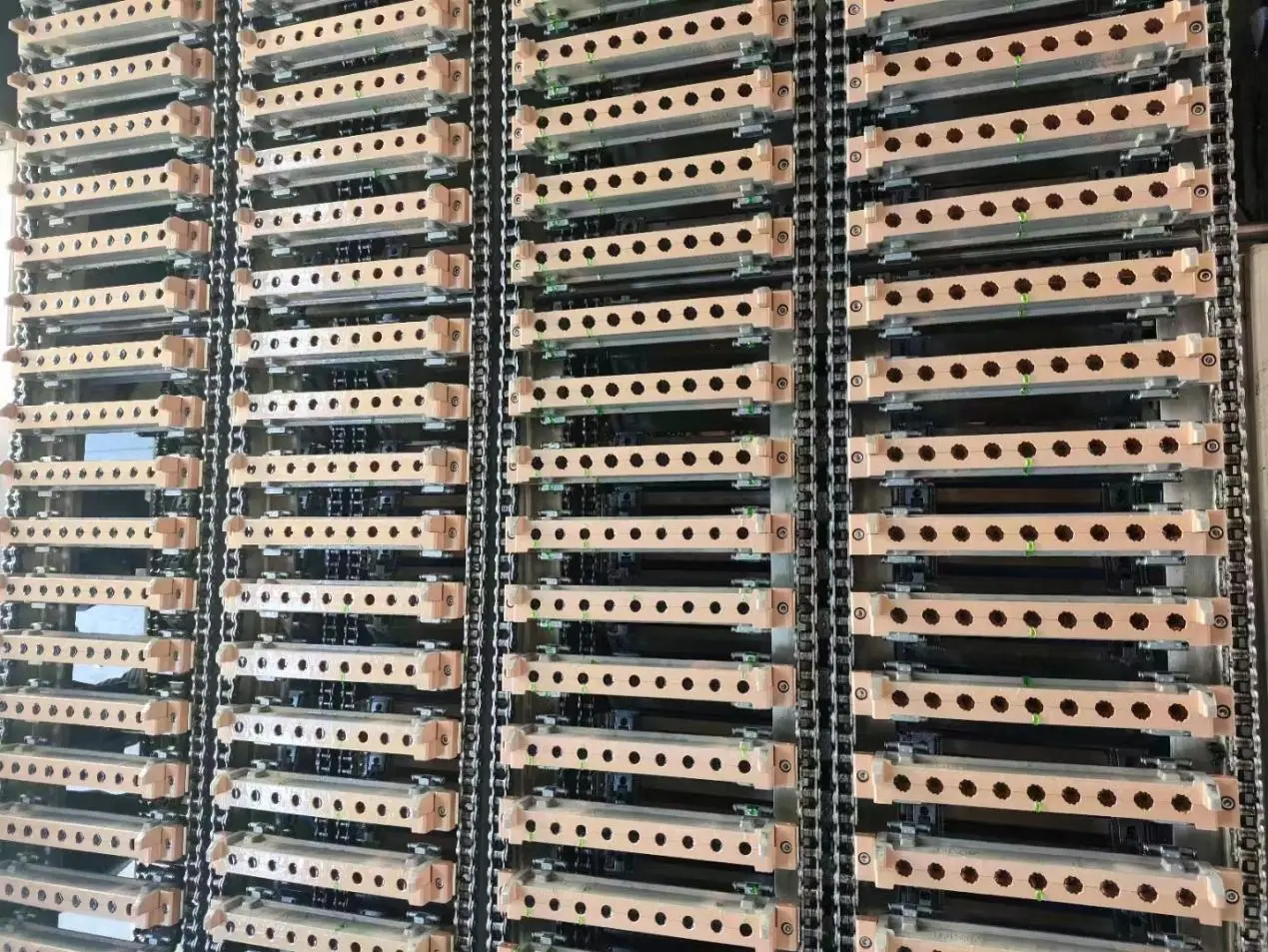

C:Depositing and cooling section

This part consist of Jelly candy Depositor ,Main drive and Mould carrier conveyor,Air-conditioner, and fan system,Discharge conveyor,De-moulding device,Cooling tunnel,PLC control system,Mould oil sprayer system

E :Final products treatment system

Double layer

jelly candy depositing line can make candy’s surface with humidification feeling and make a preparation for the next stage (to be coated with sugar granules) after the whirlpool jet ejector through a device which can filter and separate steam and water. So it can enable the sugar to be adhered on the surface of candies.