66 Available Coupons

GDQ450 Jelly Depositor Machine for Gelatin, Pectin & 3D Jelly Candies

Usage scenarios:

The GDQ450 is perfect for candy manufacturers producing gelatin or pectin-based sweets. It helps bakeries create colorful 3D jelly decorations. The machine is also useful in food labs for testing new jelly candy recipes efficiently.

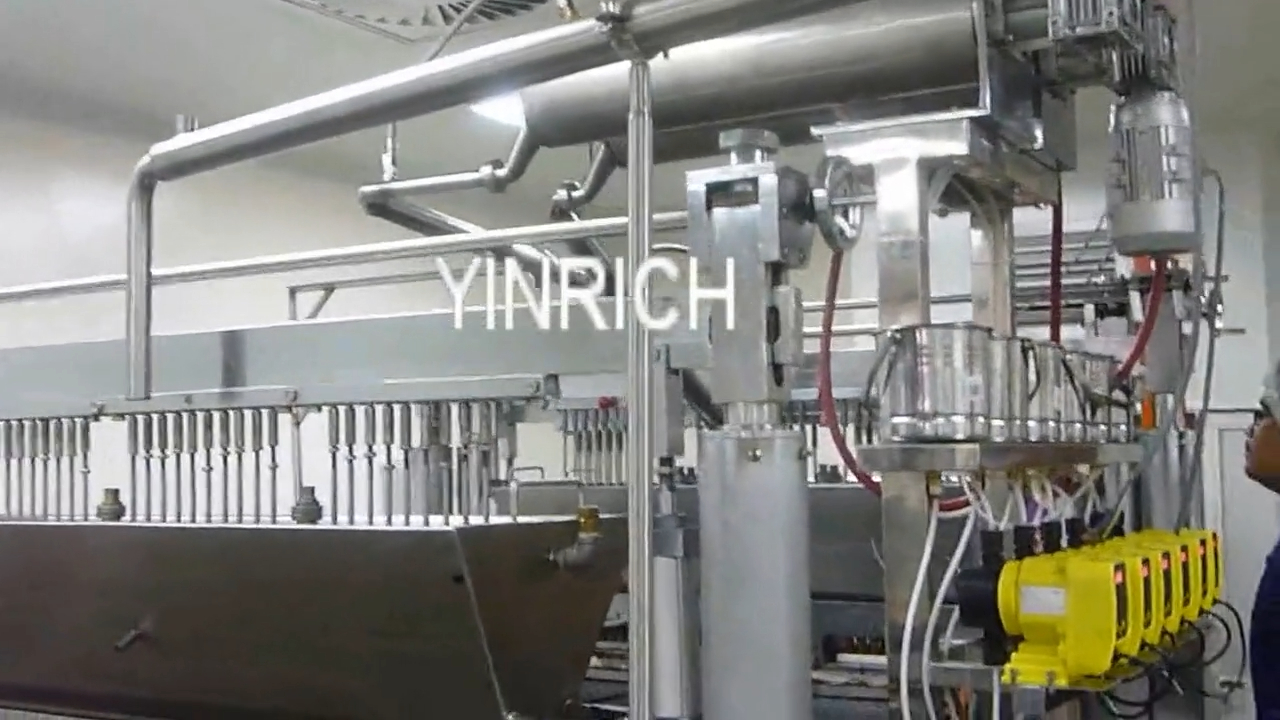

GDQ450 Jelly candy deposit line

This production line can produce gelatin or pectin based jelly candy , also can produce the 3D jelly candies. The depositor also can be used to produce the deposited toffees via change-over the moulds.

The whole line consists of batch-wise jelly cooking system, FCA(flavor, color, and acid) dosing and mixing system, multi-purpose candy depositer ,cooling tunnel ,sugar coating machine, or oil coater.

Product advantages

The GDQ450 Jelly Depositor Machine offers precise and efficient depositing for gelatin, pectin, and 3D jelly candies, ensuring consistent quality with every batch. Crafted with durable materials and advanced technology, it supports multiple molds and customizable settings to enhance production flexibility. Key features include high precision pump systems, easy operation, and seamless integration into various confectionery processes, making it ideal for scalable candy manufacturing.

Company profile

Founded with a commitment to innovation and quality, our company specializes in designing advanced food processing machinery tailored for confectionery production. The GDQ450 Jelly Depositor Machine exemplifies our core strengths in precision engineering and reliable performance, delivering consistent shaping of gelatin, pectin, and 3D jelly candies. We prioritize efficiency, durability, and user-friendly operation, helping manufacturers optimize productivity and maintain product excellence. Backed by expert craftsmanship and responsive support, our technology drives success in competitive markets by combining cutting-edge design with practical value, ensuring seamless integration into diverse production environments worldwide.

Enterprise core strength

Established with a commitment to innovation and quality, our company specializes in manufacturing advanced confectionery machinery, including the GDQ450 Jelly Depositor Machine. Renowned for precision engineering and reliability, we deliver equipment designed to optimize production efficiency and product consistency for gelatin, pectin, and 3D jelly candies. Our solutions empower confectionery manufacturers to achieve superior texture and intricate designs, elevating their product offerings. With a focus on cutting-edge technology, customer-centric service, and sustainable practices, we strive to support the growth and success of businesses worldwide by providing durable, easy-to-use, and customizable machines tailored to diverse production needs.

1) PLC /computer process control available;

2) An LED touch panel for easy operating;

3) The production capacity is 360kgs/h(based on 4.0g mono candy );

4) The contacting food parts are made of hygienic Stainless Steel SUS304

5) Optional (mass) flowing controlled by Frequency inverters ;

6) In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

7) Dosing pumps for the automatic injection of colors, flavors and acids;

8) One set of extra jam paste injection system for making fruit jam-center filled candies(optional);

9) Use automatic steam control system instead of the manual steam valve which control a stable steam pressure supplying to the cooking .

10) “two color stripe depositing”, “double- layered depositing”, “central filling”, “clear” hard candies and etc. can be made.

11) Moulds can be made according to the candies samples provided by the customer.

YINRICH® is the leading and professional exporter and manufacturer in China

We providing the high-quality confectionery , chocolate and bakery processing and packaging machinery .

Our factory located in Shanghai ,China. As the top-leading corporation for the chocolate and confectionery equipment in China, YINRICH manufactures and supplies a complete range of equipment for the chocolate and confectionery industry, ranging from single machines to complete turnkey lines, not only the advanced equipment with competitive prices ,but the economical and high efficiency of the whole solution method for the confectionery machines . \

12 months warranty since the date of installation.

- Company NameYINRICH

- E-mailsales@yinrich.com

- TEL+86-13801127507, +86-13955966088

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer