Continuous Chocolate Moulding Line with PLC Control for Quality Products - Chocolate Enrobing Equipment

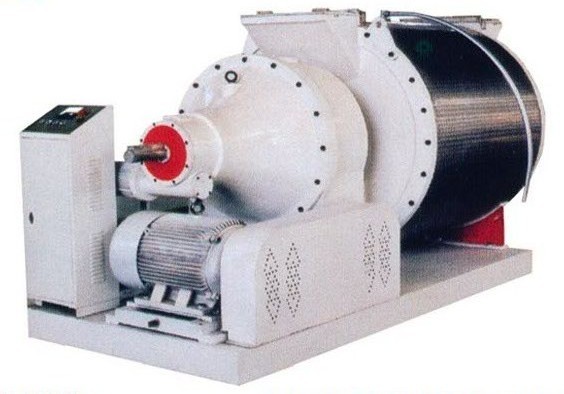

The QJ series chocolate moulding line can continuously produce various kinds of chocolate products. It is a PLC controlled machine which consists of mould heating, depositing, vibrating, cooling, de-moulding and etc.. It can produce out good quality chocolate products such as “two color”, “ central filling”, and Pure solid chocolate products.

Product advantages

Our Continuous Chocolate Moulding Line with PLC Control ensures high quality chocolate products with precise control over the production process. The chocolate enrobing equipment allows for seamless coating of various confectionery items, resulting in a smooth and glossy finish. With advanced features and automation, this equipment maximizes efficiency and consistency in chocolate production.

Team strength

At our company, our team strength lies in our collective experience and expertise in producing high-quality chocolate moulding lines. With a focus on innovation and precision, our team uses advanced PLC control technology to ensure that every product coming off our Continuous Chocolate Moulding Line meets the highest standards of quality. Our dedicated team members work seamlessly together to deliver efficient and reliable chocolate enrobing equipment that exceeds customer expectations. By leveraging our team's strengths in engineering, manufacturing, and customer service, we are able to provide our clients with top-notch solutions that improve their production processes and product quality.

Why choose us

Our Continuous Chocolate Moulding Line with PLC Control for Quality Products - Chocolate Enrobing Equipment is a testament to our team's strength in innovation and quality craftsmanship. Our dedicated team of engineers and technicians work tirelessly to ensure that every piece of equipment is designed and built to the highest standards. With our collective expertise and attention to detail, we are able to deliver a product that meets the demands of even the most discerning chocolatiers. Trust in our team's commitment to excellence and let us help you create delicious, high-quality chocolate products with our state-of-the-art enrobing equipment.

chocolate mould line have different models with different capacity.

Main Equipment list:

| Item | Equipment | specification |

| 1. | HOT WATER CIRCULATING TANK | |

| 2. | OIL MELTING OVE | RYG-30 |

| 3. | SUGAR GRINDER | FTY250 |

| 4. | CONCH | JMJ50 |

| 5. | WARM KEEPING TANK | BWG500 |

| 6. | Chocolate moulding plant(one shot head) (INCLUDING THE COOLING TUNNEL) | QJ150 |

| 7. | TRANSPORTING PUMP | SJB32 |

| 8. | CONTROLLE | |

| 9 | MOULDS | |

| 10 | CONNECTING PIPES &VALVES | |

| 11 | packing machine | BM280 |

Appendix: TECHNICAL SPECIFICATIONS FOR EACH EQUIPMENT:

1. OIL MELTING OVEN

Technical specifications:

Oil melting capacity: 2 x120=240kgs

Oil melting time: 30~60min

Heating method: Steam and power heating

Oil melting temperature: 40~65C

Dimension: 1300 x 650 x1000mm

2. SUGAR GRINDER:

Technical specifications:

Main drive motor power: 7.5KW

Feeding motor power: 1.5KW

Main drive speed: 3800 rpm

Feeding drive speed:280rpm

Dimension: 1240 x 960 x 1730mm

3. CONCH

Model: JMJ500

Max. capacity: 500liter

Fineness :20~25um

Main drive speed: 33rpm

Fine milling time: 16~22 hours

Power: 15KW

Dimension: 2000 x 1860 x 1250mm

Model: JMJ1000

Max. capacity: 1000liter

Fineness :20~25um

Main drive speed: 33rpm

Fine milling time: 14~22 hours

Power: 22KW

Dimension: 2700 x 1350 x 1800mm

4. WARM KEEPING TANK

Model:BWG500

Max. capacity: 500liter

Main drive speed: 23.5 rpm

Power: 1.5 KW

Dimension: dia.1000 x 1380mm

Model:BWG1000

Max. capacity: 1000liter

Main drive speed: 24 rpm

Power: 2.2KW

Dimension: dia.1250 x 1850mm

5. CHOCALATE DEPOSITER WITH COOLING TUNNEL(one head version)

Model: QJ150(old)

Technical specifications:

Production capacity: 0.8~2.5tons/h

Power: 21KW

Refrigerator ‘s capacity: 15000~21800kcal/h

Dimension:15330 x1210 x 2200mm

Pieces of mould plates: 220 pcs

6. CHOCALATE TRANSPORTING PUMP

Model:SJB32

Motor power: 1.5KW

Main drive speed:127rpm

Capacity: 32liter/min

Length of Pressure: 2m

Dimension: 800 x 390 x 350mm

DELIVERY DATE:

Within 60 days upon the receipt of the down payment

DELIVERY:

Ex. Our Works at Shanghai, China

TERMS OF PAYMENT:

40% by T/T as the down payment, the balance of 60% shall be pay before shipment.

OTHERS:

Testing & training:

The plant layout design, assembling and installation, start-up and local team training will be FREE at no cost. But the buyer should be responsible for the round-air tickets, local transportation, board & lodging ,and US$60.-/day/person for the pocket money to our technicians. The testing people will be two persons, and will cost 20~30 days.

Utilities:

The buyer should prepare sufficient electric power, water, steam and compressed air supplies which are suitable to be connected to our machinery before the arrival of our machinery.

WARRANTY:

The seller guarantee the quality of the products for 12 months since the date of installation . During the warranty period, any problems/defaults happen on the hard parts of the machinery ,the seller will replace the parts or send the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of the buyer, or the buyer need the technical assistance for the processing problems, the buyer should be responsible for all the cost and their allowance.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer