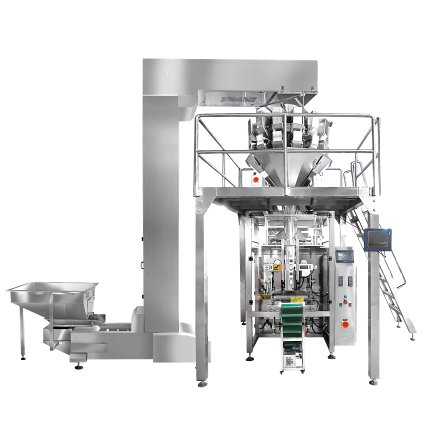

Main Equipment

1.Automatic Vertical form-fill-seal packing machine

2.14 Heads Compact weigher

3.collecting hopper

4.Z type bucket elevator(vibration)

5.Supporting platform

6.bag former

For automatic gummies packaging machines, the best choice depends on production speed, packaging type (flow-wrap, bag, stick, etc.), high-speed packaging (up to 1,000 packs/minute for advanced models), adjustable to accommodate different sizes/shapes, and optional multi-channel feeding for increased output.

This candy packaging equipment features an automatic vertical form-fill-seal system combined with a 14-head compact weigher and advanced PLC control for high-speed, precise packing of various gummy types, including functional and sugar-coated gummies. Its servo motor-driven film drawing and sealing mechanism ensure consistent bag formation with options for pillow, standing-bevel, or punch bags, while integrated functions like feeding, measuring, sealing, and date printing streamline the entire packaging process. Designed with durable components and a user-friendly wide touch screen interface, this machine maximizes efficiency and reduces waste, making it ideal for versatile gummy packaging applications.

We serve by providing cutting-edge packaging solutions tailored for the confectionery industry. Our Automatic Gummies Packaging Machine delivers high-speed, precise, and versatile packing for multiple candy sizes, ensuring efficiency and consistency in your production line. Designed for durability and user-friendly operation, it minimizes downtime and maximizes output. With advanced technology and customizable settings, we empower manufacturers to meet growing market demands while maintaining product quality. Our commitment extends beyond machinery—we offer reliable support, seamless integration, and expert guidance to help your business thrive. Experience packaging excellence with a partner dedicated to your success.

We serve manufacturers and businesses seeking efficient, reliable, and versatile packaging solutions. Our Automatic Gummies Packaging Machine delivers high-speed performance, accommodating multiple candy sizes to enhance productivity and reduce downtime. Engineered with precision and advanced technology, it ensures secure, consistent packaging that maintains product quality and freshness. We prioritize ease of use, seamless integration into existing production lines, and minimal maintenance requirements. By choosing our machine, you gain a trusted partner dedicated to optimizing your packaging process, improving operational efficiency, and supporting your growth in the competitive candy market. We serve your success with innovation and excellence.

Ordinary gummies (such as gummy bears, fruit-flavored gummies)

Functional gummies (vitamins, probiotics, CBD gummies)

Gum-based gummies (bubble gum, chewing gum)

Sugar-coated gummies (coated with sugar or acid powder)

Main Equipment

1.Automatic Vertical form-fill-seal packing machine

2.14 Heads Compact weigher

3.collecting hopper

4.Z type bucket elevator(vibration)

5.Supporting platform

6.bag former

* Famous brand PLC control system, wide version touch screen, convenient to operate..

* Film drawing down system and horizontal sealing controlled by servo motor;

* Perfect alarm system to reduce waste;

* It can complete feeding, measuring, filling, sealing, date printing, charging (exhausting), counting, finished product delivery when it equips with feeding and measuring equipment;

* The way of bag making: the machine can make pillow-type bag and standing-bevel bag, punch bag or according to customer’s requirements.

Technical parameter

Technical parameter | Content |

Capacity | 40-60 bag/min |

Bag size | (L)50-200 (W) 60-150mm |

Bag type | Pillow-type bag, standing-bevel bag, punch bag |

Max film width | Max 320mm |

Film thickness | 0.04-0.09mm |

0.04-0.09mm | 0.6Mps 0.25m3/min |

Main power/voltage | 2.2KW/ 220V 50Hz |

Dimension | L1110*W800*H1130mm |

Weight | 350kg |

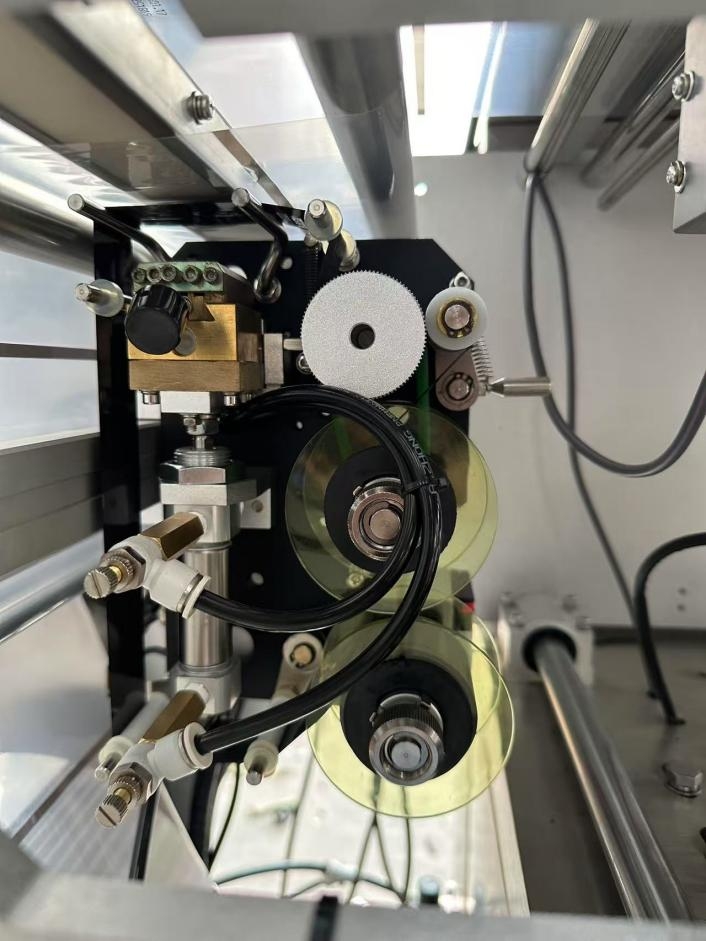

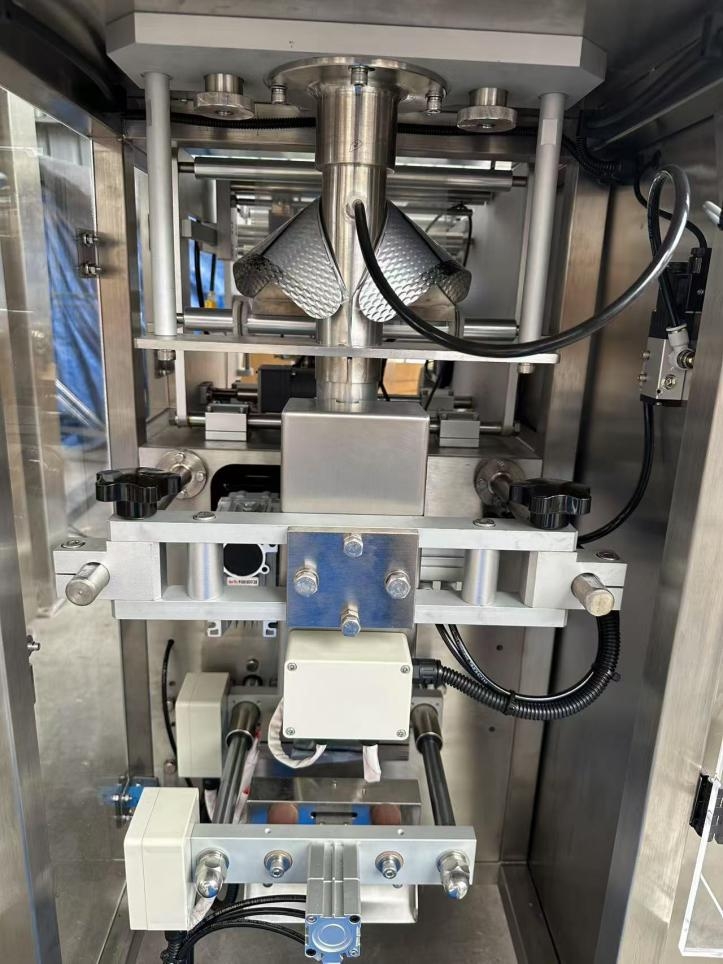

Machine detail photos

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer