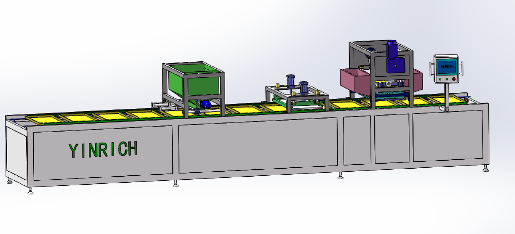

Advanced Starch Moulding Line for Two-Color Jelly Candy Production

The processing line is a advanced and continuous plant for makingstrach jelly candy,

this video shows it make the two color side by side cola bottle shape starch moulding line;

jelly candy producetion line have two different kinds of types,one is deposit line,another is starch moulding line.

the jelly candy which make by starch line is have more option of the shapes. cistomer can choose accordingly.

Product features

The Advanced Starch Moulding Line for Two-Color Jelly Candy Production streamlines the jelly candy manufacturing process through integrated equipment, including jelly mixing, flavor dosing, starch molding, and drying sections, ensuring consistent quality and efficient production. Its modular design combines core functions like precise ingredient dosing and optional aeration with value-added features such as free layout design, installation, and trial production support, enhancing operational flexibility. Built for durability and ease of maintenance, the system supports long-term reliability with comprehensive after-sales service, including warranty coverage and technical assistance.

Team strength

Our Advanced Starch Moulding Line for Two-Color Jelly Candy Production is backed by a highly skilled and dedicated team with deep expertise in confectionery machinery. Combining engineering excellence and innovative design, our team ensures seamless integration of cutting-edge technology to maximize efficiency and product quality. Their commitment to precision manufacturing and continuous improvement guarantees reliable, high-performance equipment tailored to meet complex production demands. This collaborative strength enables quick problem-solving, customization, and ongoing technical support, delivering exceptional value to customers seeking to elevate their candy production with superior consistency, speed, and aesthetic appeal.

Why choose us

Our Advanced Starch Moulding Line for Two-Color Jelly Candy Production is backed by a highly skilled, multidisciplinary team dedicated to innovation and quality. With extensive expertise in confectionery machinery design, automation, and process optimization, our team ensures reliable performance and precise color control. Committed to continuous improvement, they leverage cutting-edge technology and industry best practices to deliver efficient, scalable solutions that enhance productivity and product consistency. This strong collaborative effort drives superior craftsmanship, timely support, and customized services, empowering manufacturers to achieve exceptional two-color jelly candy production with confidence and ease.

Equipment list:

1.jelly mess kitchen equipment

2.flavor,color ,acid dosing and mixing uint

3.areater mass layer part(opertional)

4.starch moulding machine

5.accessory equipment

6.drying section

Photos in production:

SERVICES AFTER SALES

FREE layout design;

FREE assembling and installation;

FREE trial-Production and local team training;

FREE recipes.

WANTTANTY:

1. The seller guarantee the quality of the machines for 12 months since the date of installation . The seller will supply the 2 years spares for

FREE together with the machines;

2. During the warranty period, any problems/defaults happen on the hard parts of the machinery ,the seller will replace the parts or send

the technicians to go to the buyer’s site for repairing and maintenance at FREE. If the defaults are aroused by the defaulted operations of

the buyer, or the buyer needs the technical assistance for the further problems aroused(after the 1st FREE installation), the buyer should

be responsible for all our technician’s service cost and their allowance.

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer