Advanced Chewing Gum Production Line - Ideal for High-Quality Products

KD300 double-color\multi-color bubble gum production line is an advanced equipment for producing chewing gum, and it can also be used to make soft candies, such as toffee, toffee, etc. It is an ideal equipment for producing high-quality products. Save manpower and space. Professionally help food processing plants to provide one-stop production equipment.

Product advantages

Our Advanced Chewing Gum Production Line is perfect for creating high-quality chewing gum products with precision and efficiency. With state-of-the-art technology and innovative features, this production line ensures consistent quality and flavor in every batch. Its advanced design and capabilities make it ideal for meeting the demands of producing premium chewing gum products on a large scale.

Team strength

At our advanced chewing gum production line, our team strength is unmatched in the industry. With a highly skilled and experienced team of engineers, technicians, and quality control experts, we ensure that every gum product that comes out of our line is of the highest quality. Our team’s commitment to excellence and attention to detail guarantee that your high-quality gum products will meet and exceed customer expectations. By investing in our team, we invest in the success of your business, as we work together to create the best possible products for your customers. Trust in our team strength for exceptional results.

Why choose us

Our Advanced Chewing Gum Production Line boasts a team strength that is unparalleled in the industry. Our experienced engineers and technicians work seamlessly to ensure top-notch quality control and innovation in every aspect of the production process. With a deep understanding of the intricacies of gum production, our team is dedicated to delivering high-performance machinery that consistently produces high-quality products. From conceptualization to final output, our team's commitment to excellence shines through, making our production line the ideal choice for those looking to create top-tier chewing gum products. Trust in our team strength to elevate your production capabilities to new heights.

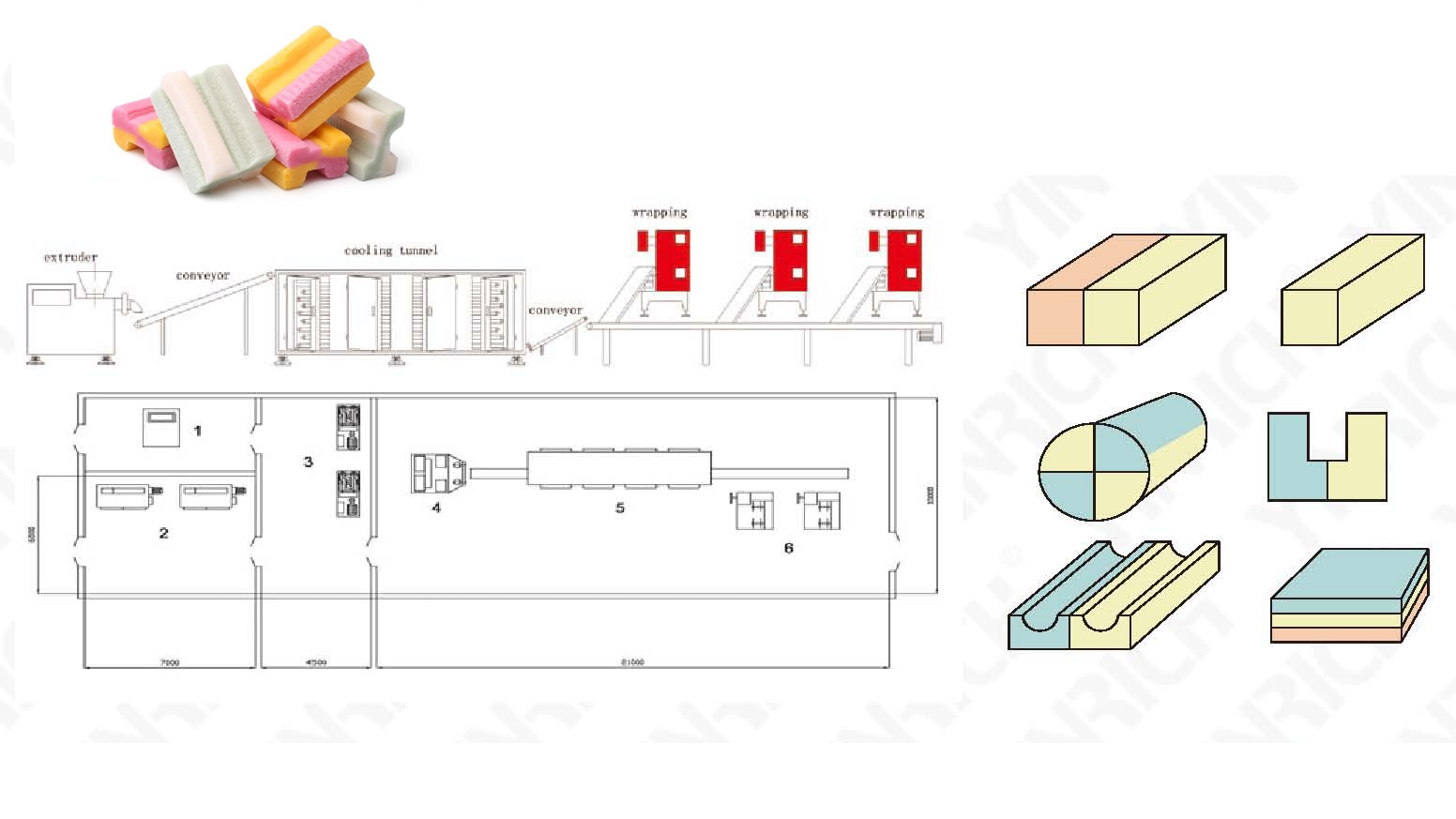

The processing line is an advanced plant for making chewing gums ,also can be used as making soft candies, such as central- filling milk candies, toffee candies and etc.. It is also an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied.

Machine specification:

| Description | Specification | total power | Capacity | Dimension |

| Mixer | 200L | 19.1KW | 200-300kg/h | 2350X8880X1250mm |

| Extruder | four screws | 18KW | 350kg/h | 2130X1500X1800mm |

| Cooling tunnel | 9 floors,cooling temp.10-15℃ | 1.5KW | 350kg/h | 2500X1200X100mm |

| cutting&fold wrapping machine | QZB500 | 3KW | 300-500pcs/min | 1450X1200X1800mm |

Machine laylout:

YINRICH founded in 2008, is located in China, We are a professional factory specialized in manufacturing confectionery equipment, assembly line for the production of candy, etc. We are mainly specialized in project, we can provide service from drawing making, technology advising, site measurement to products installation and maintenance overall service to our customers. With professional attitude, dedicated spirit and innovative concept, the products we made are economical and practical, and with good quality and novel appearance. Having introduced a series of advanced equipments and with strong professional technology team comprised of senior engineers, technologist and designers, all of these can ensure our goods are of strictly produced in accurate size and technology as high standard process, meanwhile, we are now researching new products and have found systematized sales and after-sale service system to satisfy customers’ requirement and adapt the market’s development. Now we have earned good reputation and approving from our customers. We are always insist on “Customer-centered, Quality first” service concept, we believe that we will get more and more customers’ approving as well as developing ourselves stronger day by day.

- YINRICH

- sales@yinrich.com

- +86-13801127507, +86-13955966088

QUICK LINKS

CONTACT US

Yinrich Confectionery Equipment Manufacturer